Production support software - Laser

MAZAK SMART SYSTEM

Sheetmetal CAD/CAM SMART SYSTEM

The advanced functions of the SMART SYSTEM CAD/CAM system considerably reduce the setup time required for sheetmetal processing. Easily making component drawing from finished product drawing -> quickly making development drawing and work instructions -> directly covert to NC data. The Smart System can quickly produce nesting data with optimum worksheet utilization. All processes which require considerable time for setups by traditional CAM systems- design by CAD, producing NC data by CAM, and nesting can be done much more quickly by the Smart System. Centralized program management and convenient networking are other advantages.

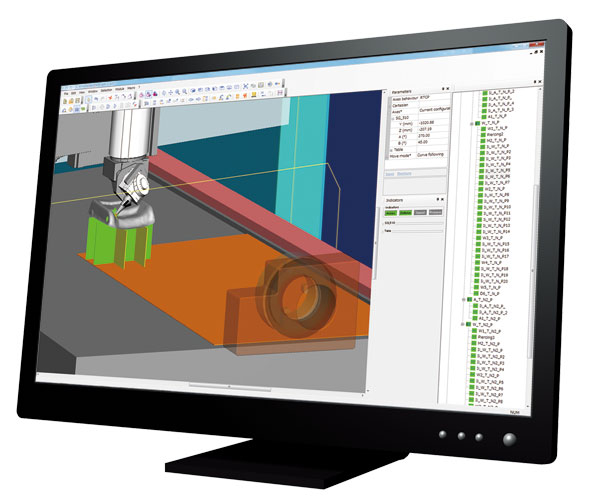

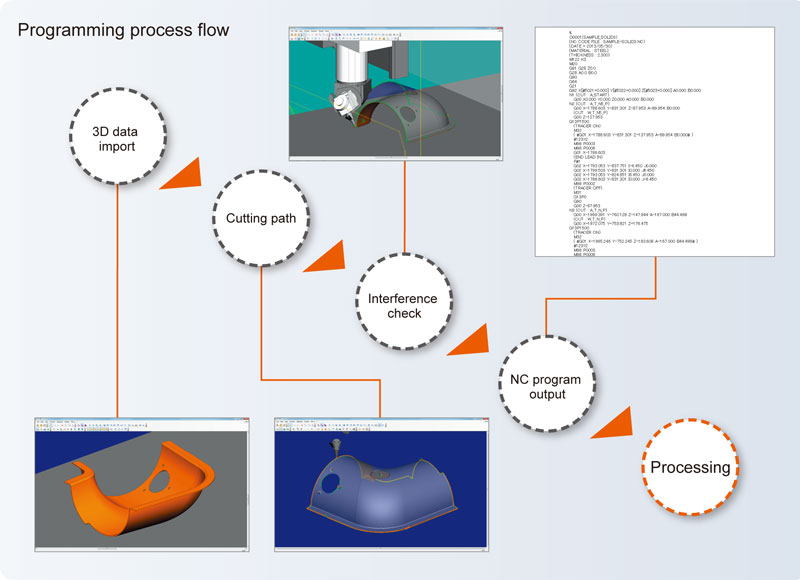

FX 3D

FX3D can instantly create a program for 3D cutting and machine processing can start immediately

FX3D can instantly create a program for the SPACE GEAR 3D laser processing series

- Automatic programming with 3D CAD data resulting in reduced setup time

- Automatically program fixtures from workpiece 3D CAD data

- High precision kinematic simulation

- Machine operation can be reproduced in the FX 3D software, making it possible to prepare a collision free program

- Reduced time required for creating NC programs resulting in unsurpassed productivity

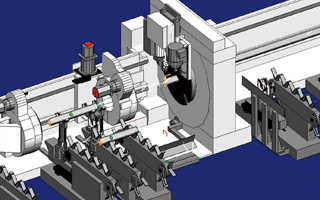

FX TUBE

FX TUBE can instantly create a program for the 3D cutting of tube or pipe, and can start machine processing immediately

- The operation can easily produce a drawing, nesting, program check and CNC program

- Off-line programming system does not reduce the beam on-time of the laser processing machine

- The import functions of the 3D model data from other CAD systems enable you to create complex and long programs instantly

- Machine operation can be reproduced in the FX TUBE software, making it possible to prepare a collision free program

- Reduced time required for creating NC programs resulting in unsurpassed productivity

Newly added features enhance productivity as well as improving ease of operation

High precision capability (Kinematic Simulation)

Simulation is performed using a virtual machine model which accurately reproduces the actual machine

Bevel cutting for easier tube welding