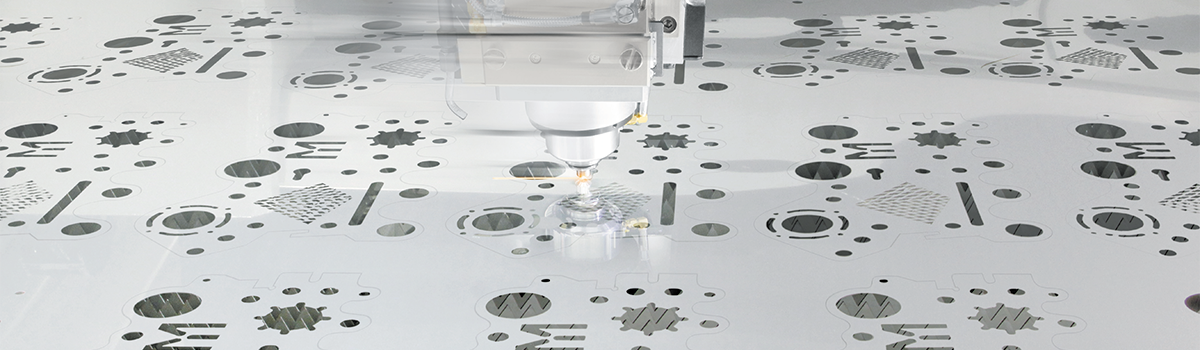

High-speed, high-accuracy laser cutting with unsurpassed productivity

Yamazaki Mazak started the production of laser processing machines in the 1980's. Ever since, we have concentrated on producing the most advanced machines available, capable of cutting thin to thick flat worksheets, cubic workpieces and pipe and structural materials - all with high-speed and high-accuracy. This is made possible by using the latest machine tool and CNC technology and CAD / CAM software while focusing on overall ergonomic machine design. Our extensive laser product range incorporating the most advanced technology is designed to meet virtually any production requirement.

The Multi-Control Torch and the variety of Intelligent Functions provide incomparable operator support for exceptional ease of operation and the optimum machine efficiencyMazak laser processing machines feature advanced functions-optimum lens and nozzle can automatically be selected and be changed for each material and thickness. Even unskilled or inexperienced operators can now easily perform high quality cutting. Improved quality of machined components as well as reduced machining time and running cost. Featuring the new Multi-Control Torch - Thanks to the flexible beam diameter, optimum cutting with high-speed and high-accuracy can be performed by automatic setup - effective for both thin worksheets and thick plates. |

Intelligent Set-Up Functions

A wide variety of automation functions is available for ease of operation and reduced setup time.

Automatically change to optimum nozzle for continuous automatic operation. Also assist gas is reduced to realize optimum cutting.

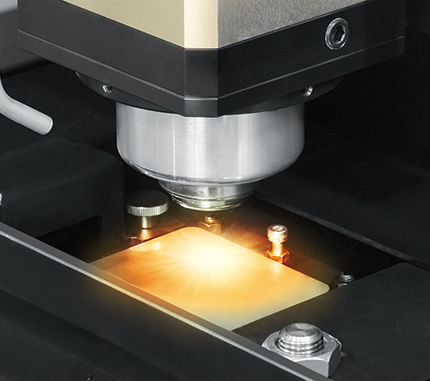

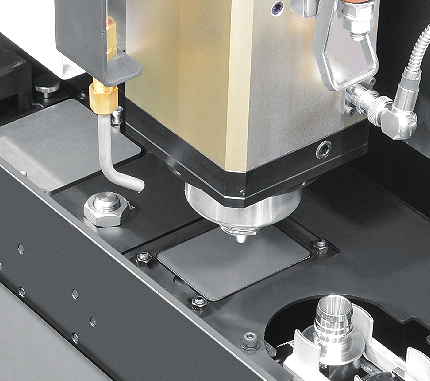

Traditionally focal distance measurement and adjustment requires considerable setup time as well as a skilled and experienced operator. Even unskilled or inexperienced operators can now easily perform these operations by using the Focus Detection system by program commands. Additionally, this system automatically compensates for focal distance changes which occur due to lens contamination.

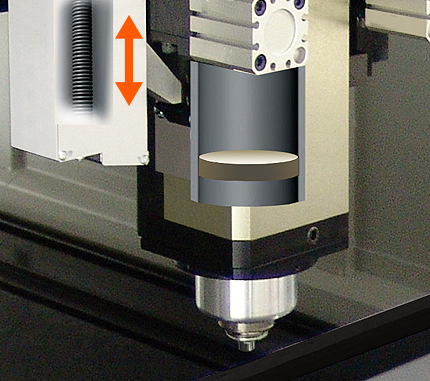

By moving a lens up or down, the focal point position can be changed automatically. As a result, the focal point can be positioned for the optimum piercing performance as well as cutting for the maximum productivity.

By moving the lens up or down, the laser beam diameter can be changed automatically. Stable cutting is realized― improved cutting speed for thin worksheets and increased cutting performance for thick sheets.

Cutting distance position must be maintained for dross free cutting. When installing a new nozzle, gap distance is properly maintained with the use of auto profiler calibration. This automatic calibration maximizes the time between necessary operator intervention.

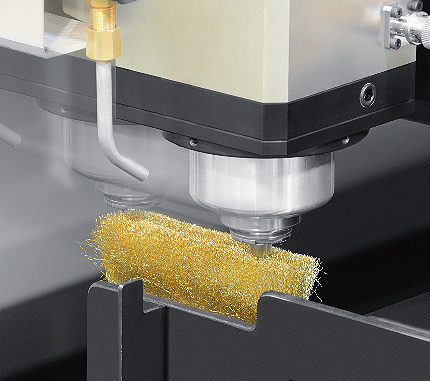

The torch head can be moved to the nozzle cleaning brush by program command which removes spatter that has adhered to the nozzle.

Intelligent Monitoring Functions

Operation status of laser processing can be monitored. The laser processing head is equipped with a sensor to check piercing and detect defects (burning or plasma).

When a defect is detected, the operation is corrected or paused to realize optimum cutting.

Normally, it is quite difficult to stabilize piercing operations for medium/thick worksheets resulting in piercing problems. The Intelligent piercing sensor detects when the laser beam pierces the material and completes hole piercing. This function ensures continuous piercing operation resulting in the minimum piercing time.

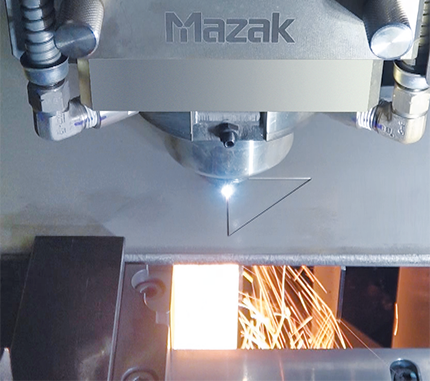

Plasma generated during cutting of medium/thick stainless steel worksheets frequently results in cutting failure that stops machine operation.

The Plasma Detection monitors plasma generation during processing and makes automatic adjustments to maintain optimum conditions for consistent cutting quality.

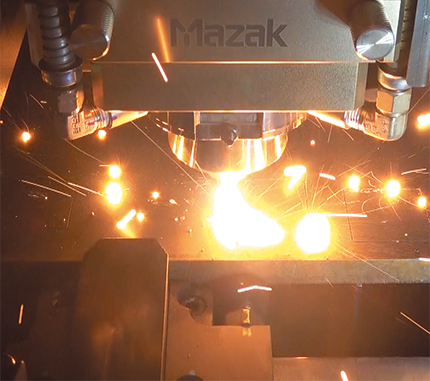

Normally burning generated during the cutting of medium/thick mild steel worksheets often results in cutting failure. The Burn Detection monitors for abnormal burning during processing and automatically stops cutting if any is detected.

If the bottom of the protective window has spatter or other contaminants adhering to its surface, cutting performance will be affected.

The protective window sensor detects a sharp temperature rise and will stop machine operation to prevent any damage to the protective window.

INTELLIGENT CUTTING FUNCTIONS

Automatic functions incorporating Mazak's expertise accumulated over many years that ensure high quality and high efficiency laser cutting.

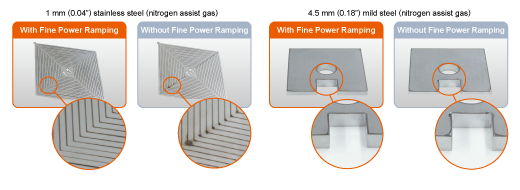

Fine power ramping function controls laser output and feedrate - optimum cutting conditions are automatically used for high speed straight and corner cutting to prevent dross.

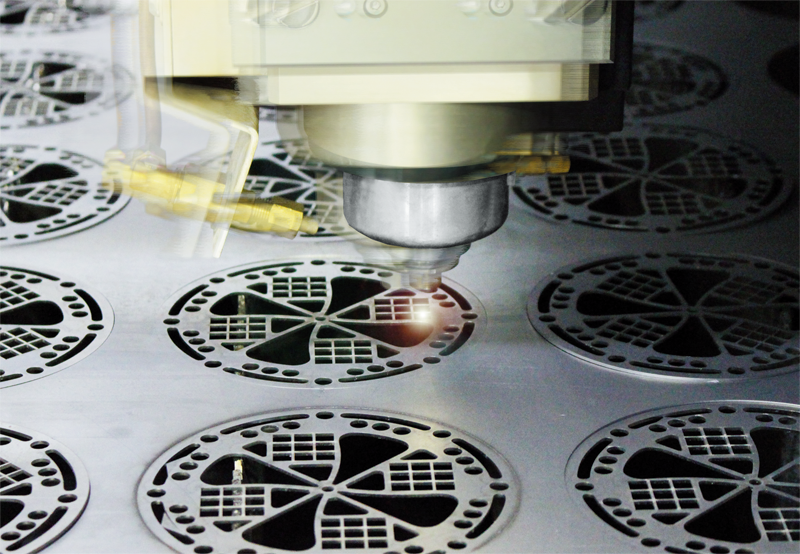

Cutting method by turning the laser ON / OFF without stopping axis.

Axis movement and laser ON / OFF are synchronized to reduce cutting time.