FSW (Friction Stir Welding) technology

Friction Stir Welding is a joining process that uses frictional heat generated by a rotating tool to join two metal plates.

Unlike conventional welding methods, FSW does not use fusible materials, or melt the workpiece.

FSW is well-suited for joining alloys with low melting points, including aluminum, copper and brass, as well as handling high-temperature welding in steels and nickel-based alloys.

Joint strength becomes higher, and distortion becomes smaller than conventional welding methods.

FSW creates safer working environment as it does not produce gas, fume, or spatter.

Productivity can be greatly improved by applying FSW to the various joining process, especially in EV and semiconductor industry.

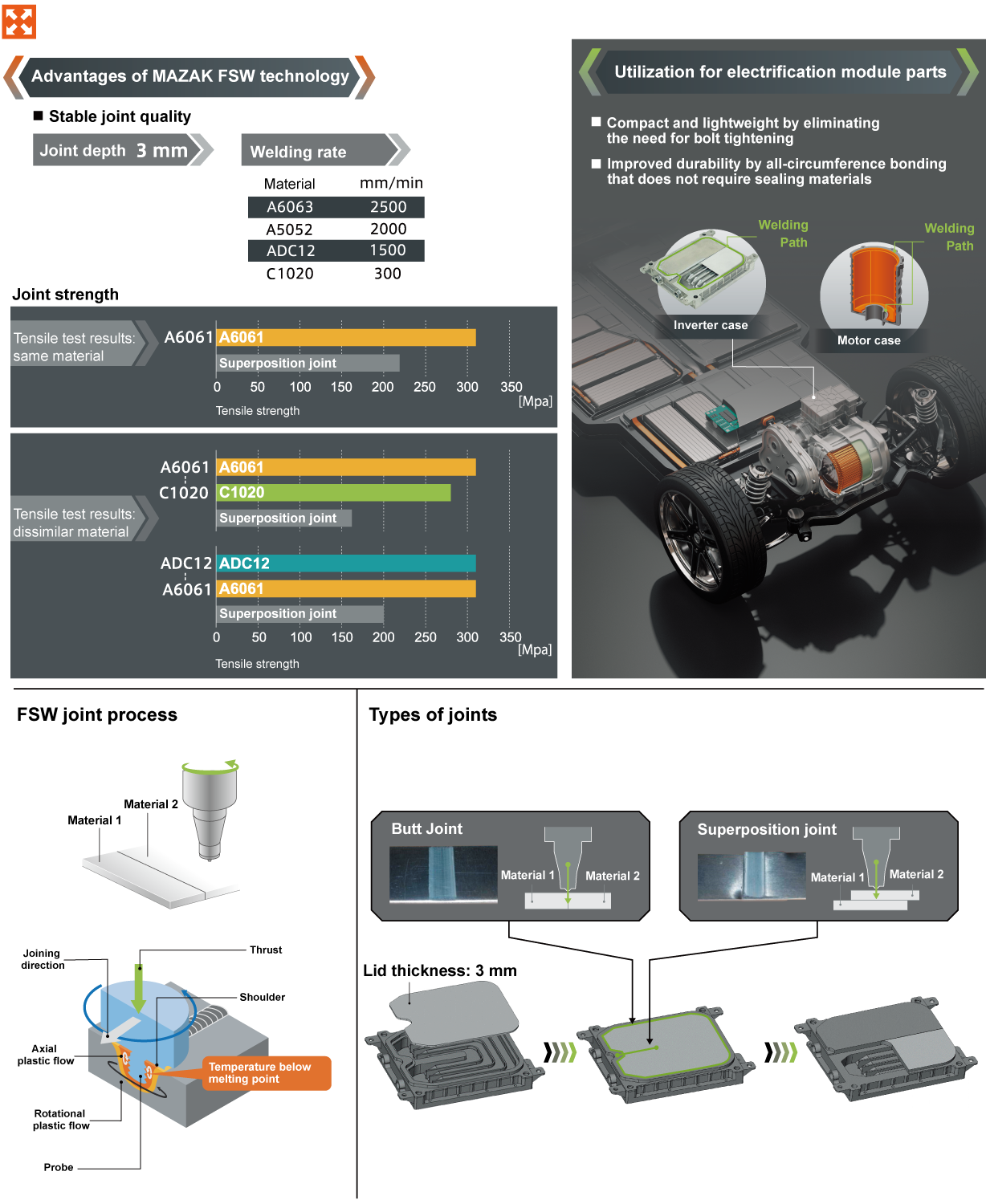

Advantages of FSW

- Creates full-penetration, defect-free welded joints with greater strength than conventional welding methods

- Able to join not only the same base metals, but also different types of metals

- Environmentally friendly; no fumes, dust, spatter, plasma or X-rays

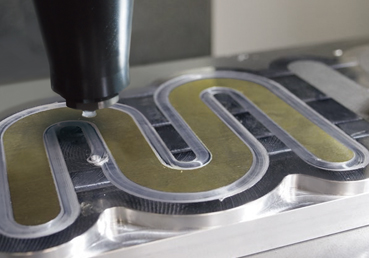

Case Study for Automotive Industry

Case Study for Semiconductor Industry

Process from machining to FSW

Application examples

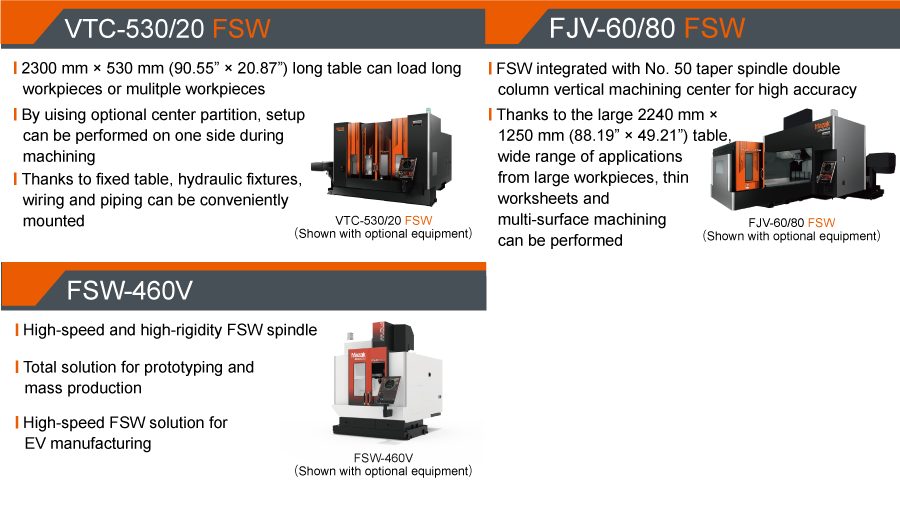

Applicable models