MAZATROL

Increase your productivity thanks to AI technology

Innovative functions for higher productivity

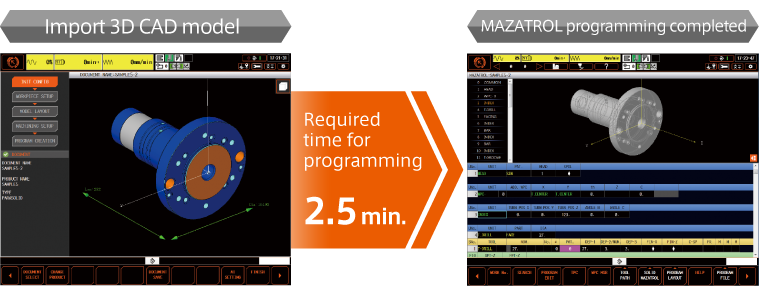

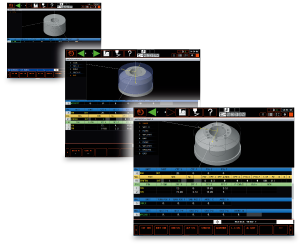

Solid MAZATROL(Available with the INTEGREX series and some of the CNC turning centers)

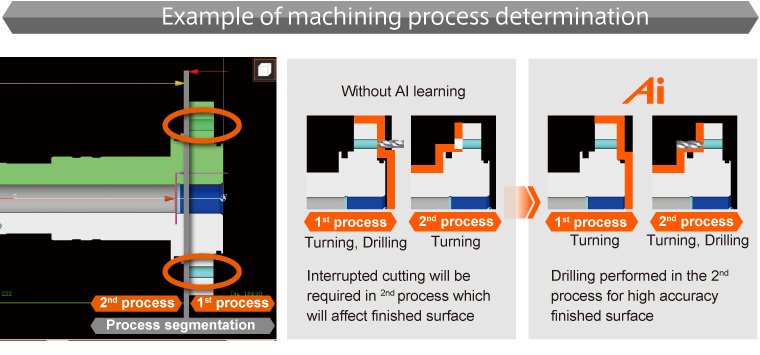

Optimize machining process by AI determination

Extremely fast programming using 3D CAD data

|

|

Smooth Ai Spindle

Optimized cutting conditions

Advanced spindle vibration detection by AI improves finished surfaces and productivity

Using AI, milling spindle vibration is detected and machining conditions are automatically changed to realize unsurpassed surface finishes and high productivity.

Ai Thermal Shield

Ensures stable machining accuracy

Ai Thermal Shield ensures enhanced heat displacement compensation

New algorithms automatically determine the amount of compensation to be automatically applied according to changes in the temperature to ensure even higher machining accuracy.

On-Machine Measurement Software for improving of production lead time

On-Machine Measurement Software

Measurement of a workpiece on the machineImproving of production lead time and prevention of defective products

- The operator does not need to load and unload the workpieces to measure it each time. This system reduces set-up time and helps prevent defects

- Elimination of variances in manual measurement results (vernier caliper・micrometer・bore gauge, etc.)

- Easy creation of measurement programs by conversational programming

- The user is required to prepare the touch probe and reference sphere for on machine measurement.

Additional purchases may be necessary depending on the customer environment.

For further details, please contact your nearest Mazak office.

Three "Ez (easy)" features for higher productivity

|

|

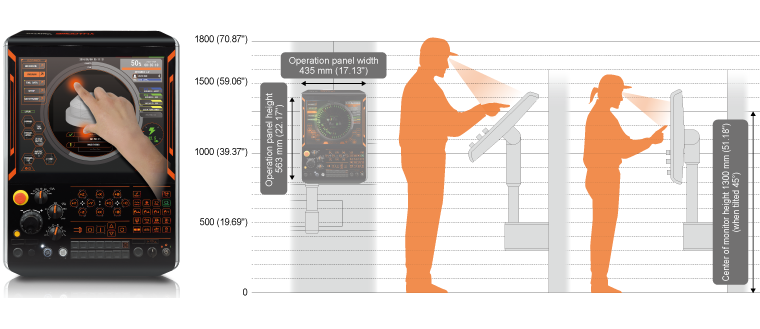

Intuitive operation with 15” touch screen

The control is responsive, efficient and easy to learn, even for new operators.

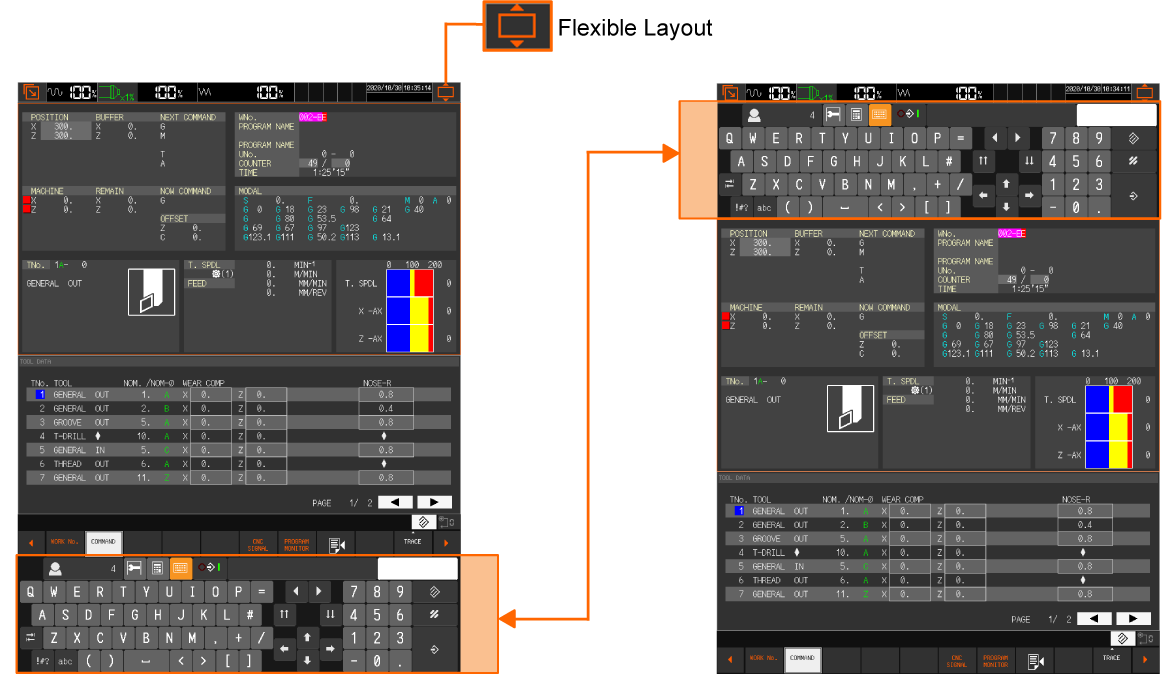

Flexible Layout

Display data, menu and screen keyboard position can be changed in the CNC screen.

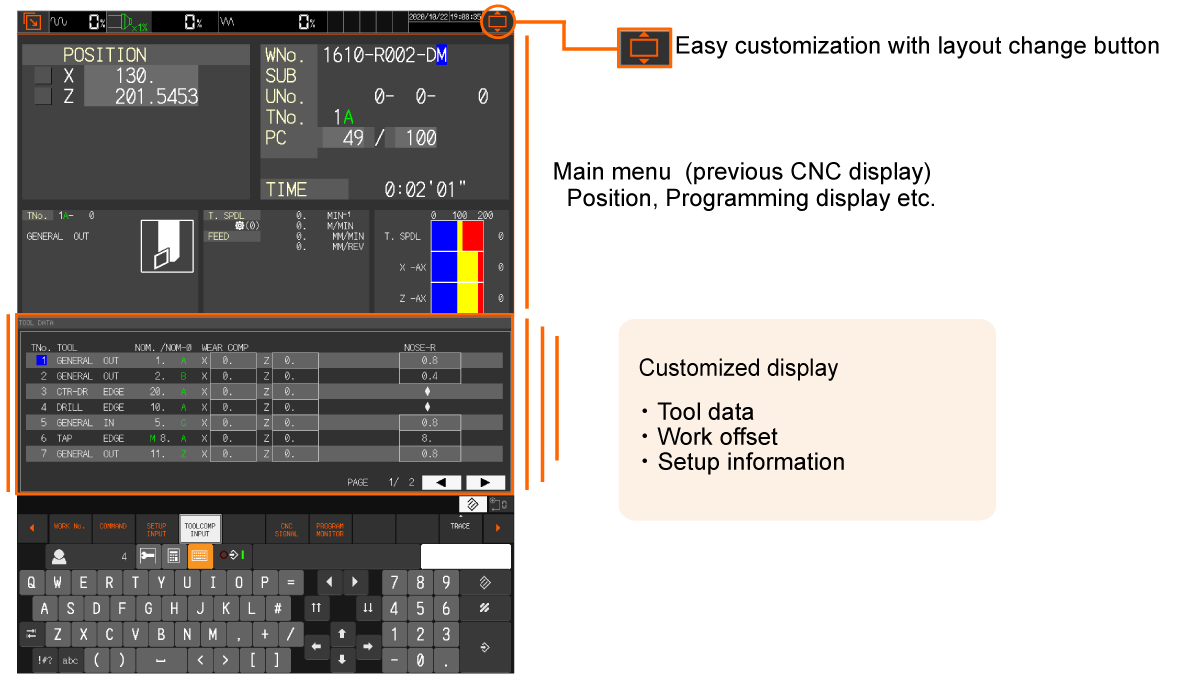

Custom Display

Various information can be displayed. Data can be checked and set with minimum screen transition by customizing the display according to operation process.

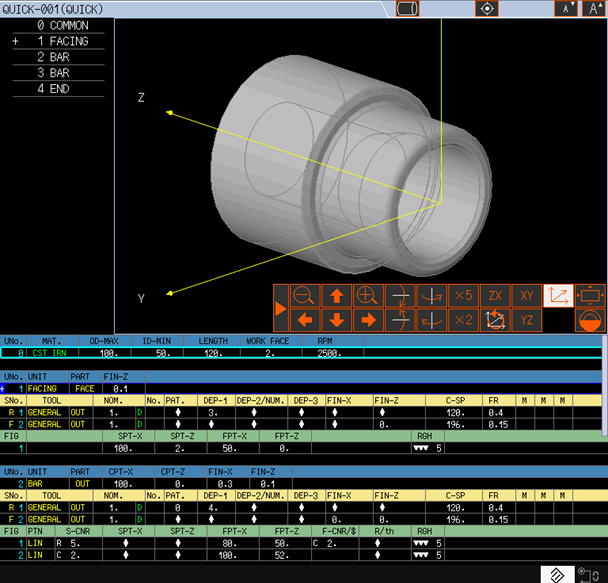

QUICK MAZATROL

QUICK MAZATROL makes it possible to reduce the programming time.

Program errors can be reduced for minimum programming time.

Programs can be easily created and checked by utilizing the touch screen and displaying the 3D workpiece model.

|

|

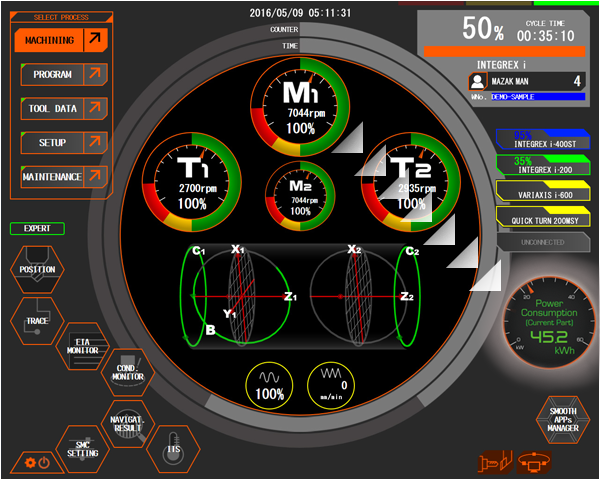

CNC for Multi-tasking machines・5-axis machining centers ・Machining centers ・CNC Turning centers

MAZATROL Smooth CNC

MAZATROL Smooth CNC series with advanced Smooth Technology -

Designed to increase your productivity

- Smooth Technology ensures higher productivity

- Fastest CNC in the world - Latest hardware and software for unprecedented speed and precision

- Unsurpassed ease of operation

- Smooth Process Support Software can integrate your machines and processes for higher productivity

Display varies by machine specifications

MAZATROL SmoothX, MAZATROL SmoothG

- Touch screen operation - Operates similar to your smartphone / tablet

- MAZATROL Smooth graphical user interface for unsurpassed ease of operation

- High precision 5-axes simultaneous machining of complex contours at high speed feedrates (MAZATROL SmoothX)

MAZATROL SmoothC

- MAZATROL programing

- Simplified display and key input operation

- Home screen and menu selection for unsurpassed ease of operation

Functions

MAZATROL Smooth CNC series

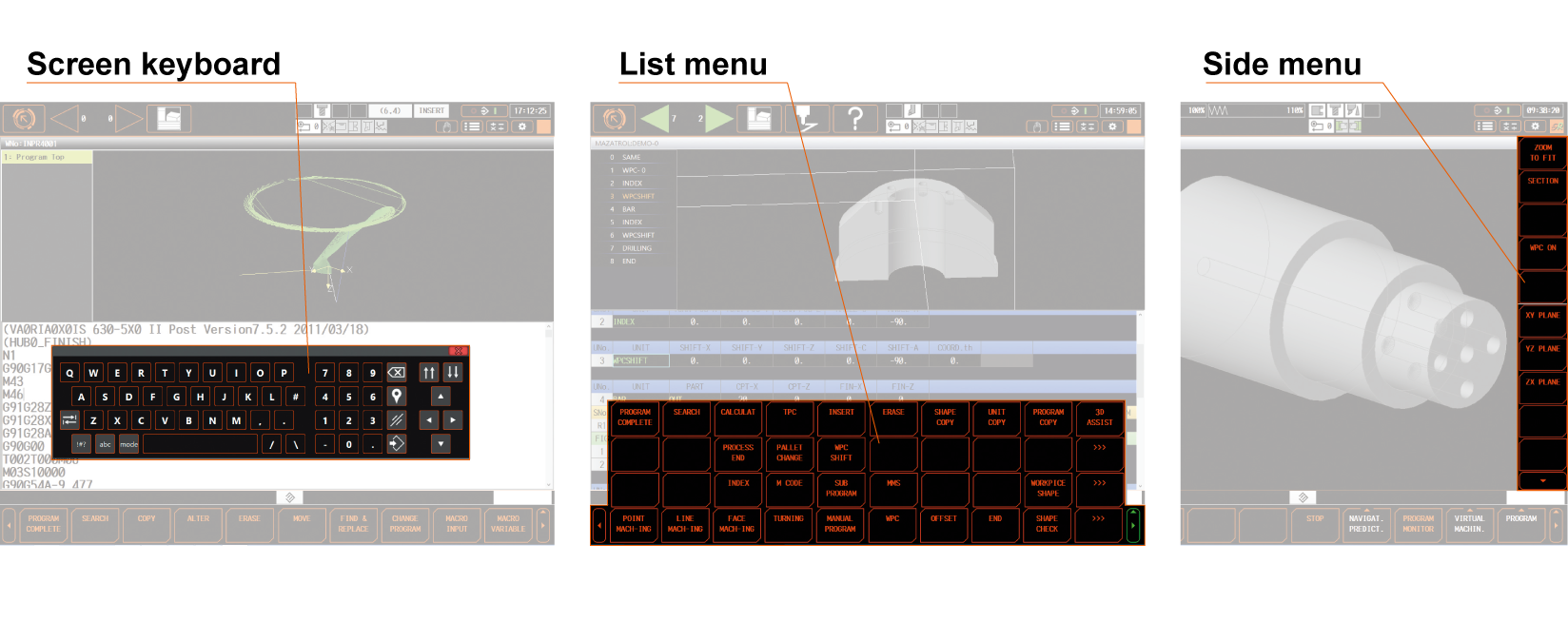

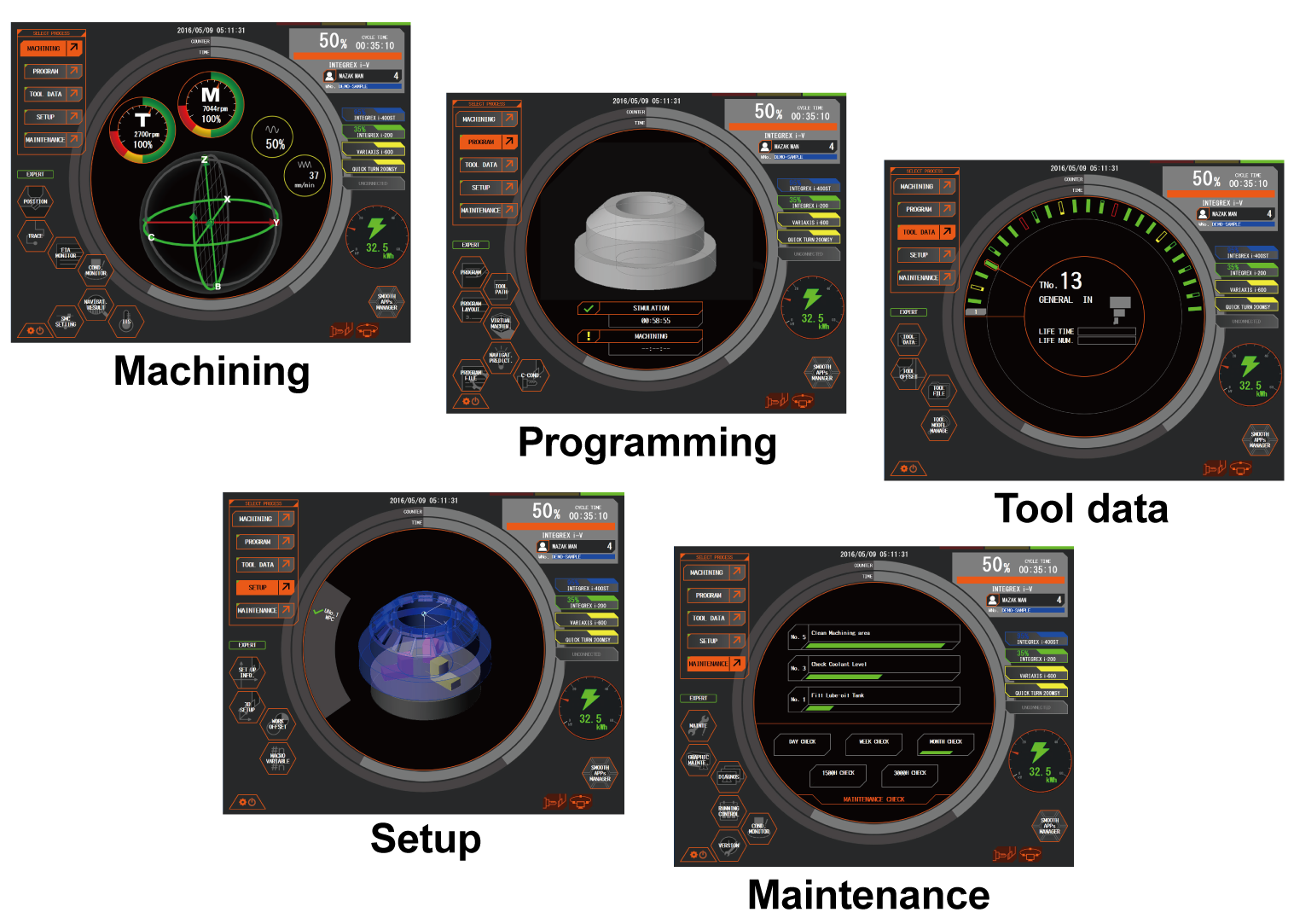

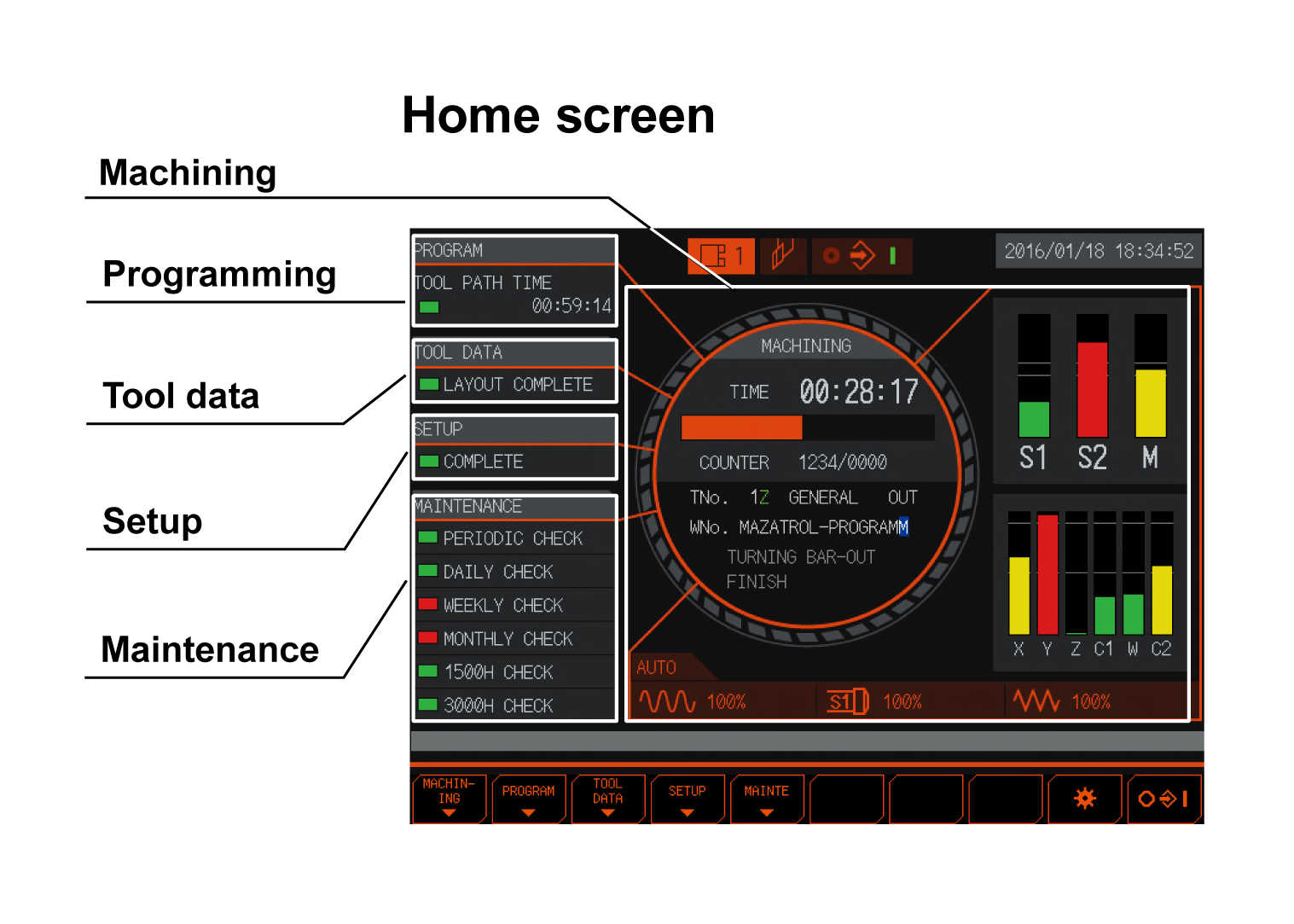

Smooth Operation

Pop-up windows are used for additional displays, selection of other items or input of values.

Smooth Machining Process

Each process has a home screen, and each home screen displays the appropriate data in an easy-to-understand manner.

Smooth Programming

- QUICK EIA

Quickly move to the corresponding section of an EIA program by touching the tool path. Any problems can be confirmed by the program analysis function

- QUICK MAZATROL

By checking shapes and processes, program errors can be reduced for minimum programming time. 3D CAD data can be imported for fast and easy programming.

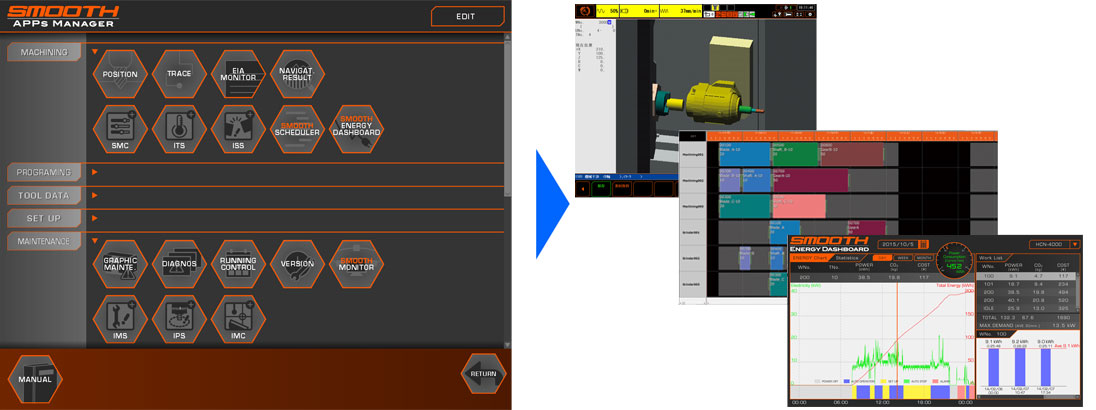

Apps Manager

Convenient management of applications and shortcuts

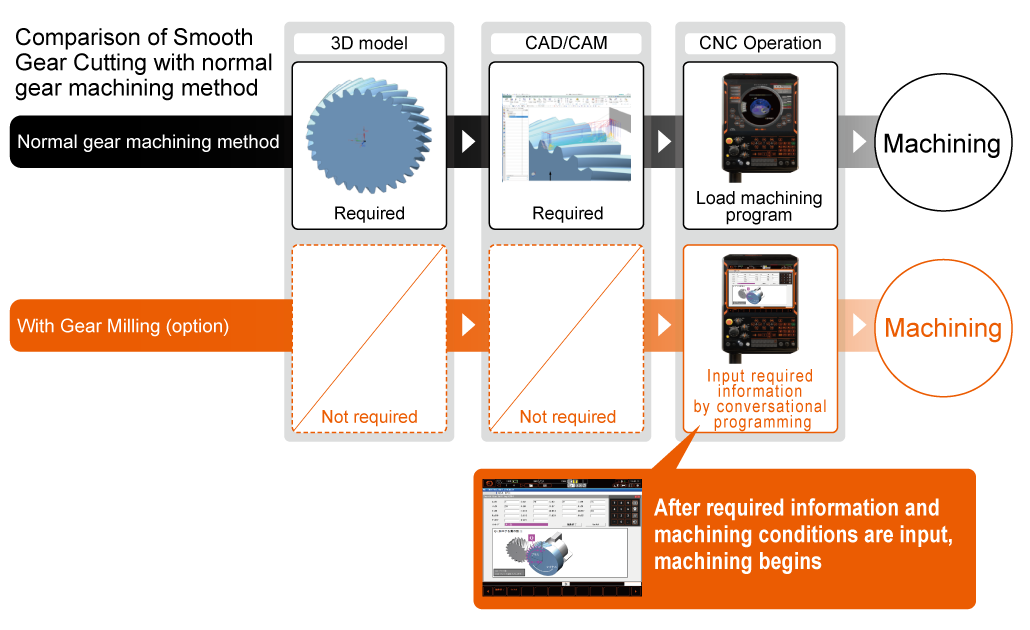

Advanced machining Gear cutting

Reduced Machining Time

Exceptional ease of operation as well as convenient visualization of data provides higher productivity.

Smooth gear cutting easily makes gear machining programs

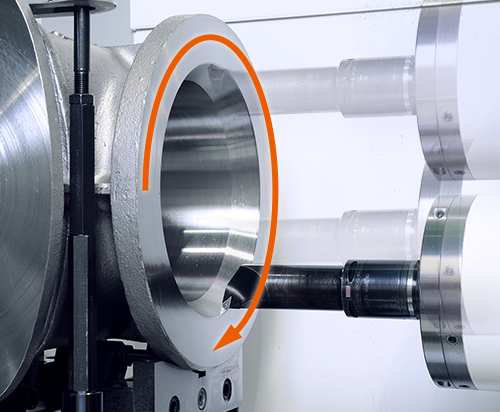

Advanced machining Orbit machining ― turned workpiece features on a machining center

|

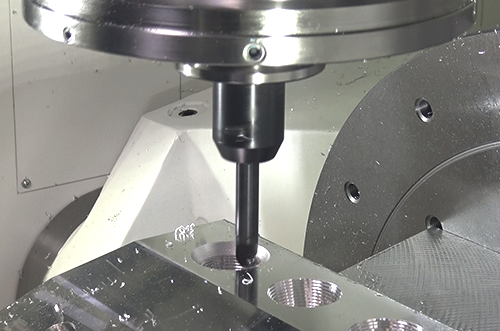

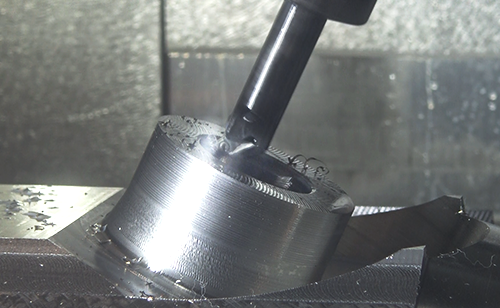

Process integration for turning on a machining center Extremely effective for machining diameters, grooves, and taper bores

|

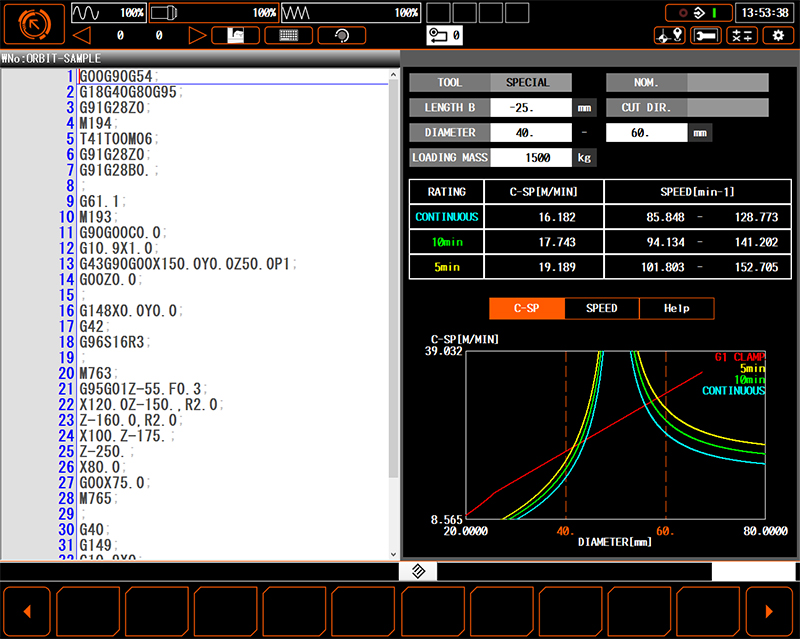

New G-code for orbit machining

|

High precision machining

|

|

Angled orbit machining

|

Orbit machining programming assistance

|

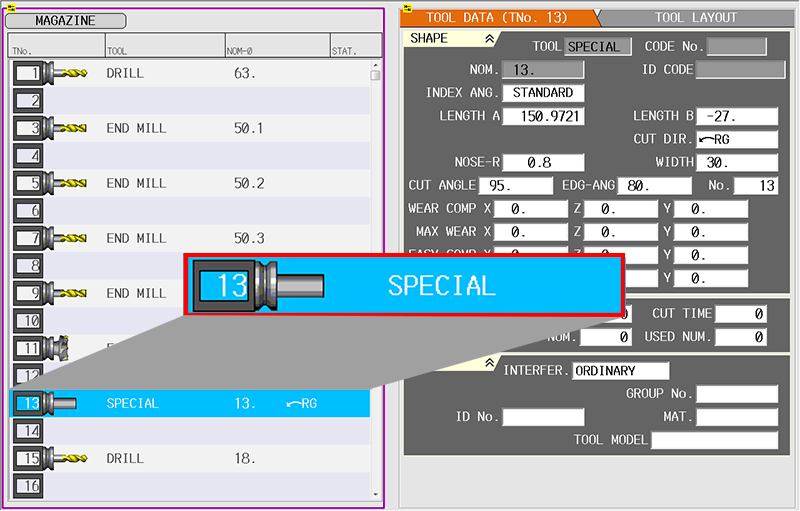

Tool registration

|

|

Orbit machining assistance

|

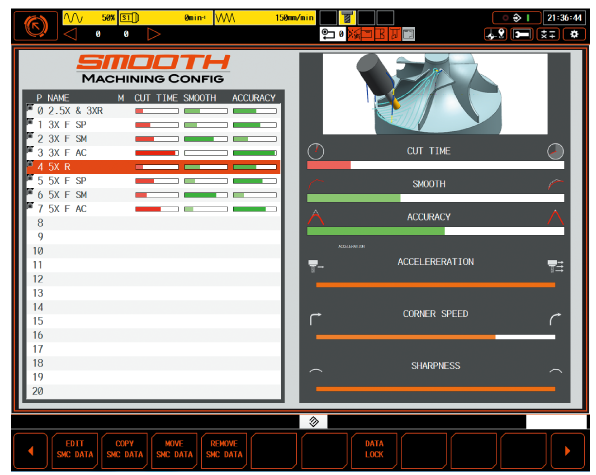

Advanced machining Smooth Machining Configuration ― convenient parameter setting and fine tuning function

![]()

Machining features including cycle time, finished surface and machining shape can be adjusted by slider switches on the display according to material requirements and machining methods.

Ones the desired results are obtained, the settings can be stored in memory so that they can be easily used again in the future.

Smooth Process Support Software

Smooth Production Management

Data sharing between SmoothX CNC and office PCs for improved production efficiency. Convenient network connection to peripheral equipment thanks to industrial network standards.

Eco-Friendly ENERGY DASHBOARD

The Energy Dashboard provides a convenient visual monitoring of energy consumption and analysis including displays of energy consumption by workpiece, approximate CO2 emission and electrical power cost.

Machine specifications

|

CNC series |

|

|

|

|

Number of controlled axes |

Simultaneous 5 axes | Simultaneous 4 axes | Simultaneous 4 axes |

| Minimum program increment unit | 0.0001 mm | 0.0001 mm | 0.0001 mm |

| Display |

19" color TFT (Touch panel) |

19" color TFT (Touch panel) |

10.4" VGA |

| Keyboard | Screen keyboard | Screen keyboard | Operation panel keyboard |

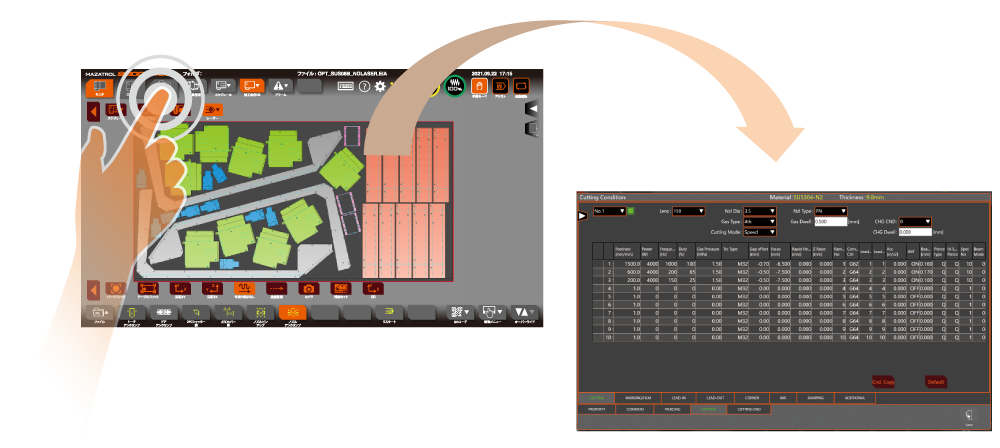

Large 21.5” Screen&Touch Panel

The widescreen enables operators to view nesting at a glance. Additionally, operators can easily zoom in and out using the touch screen display.Flat Design for Easier Operation

Operational buttons feature a flat design and icons for intuitive performance. The Emergency Stop and Rotary Switch buttons are positioned prominently to ensure easy access.Optional Dual Monitor

The additional Dual Monitor option allows multiple applications to run simultaneously. Nest Programming, Cut Monitoring, Production Scheduling and Machine Maintenance are just some of the many functions available to the operator while the machine is in operation.One-Touch Operation

Operators can easily access necessary information, like cut conditions, with the touch of a button.

Assist Functions

Operators can quickly and easily update settings by inputting specifications suggested by assist functions, like Auto Nozzle Changing and Centering.

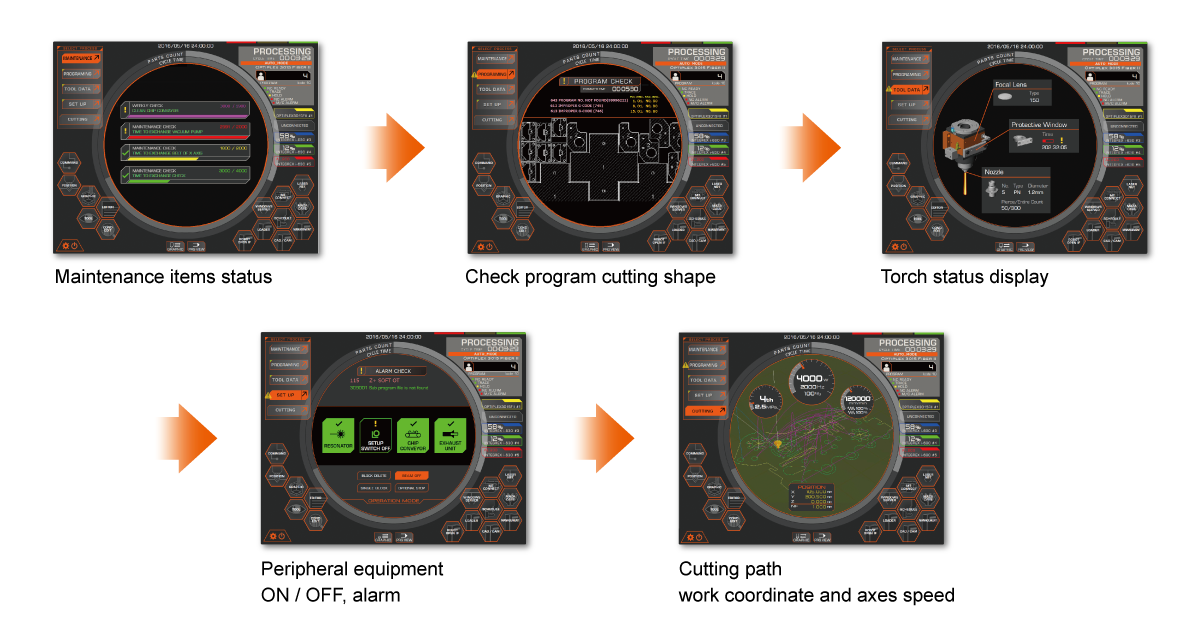

CNC for laser prcessing machines

MAZATROL PreviewG

Higher productivity by high-speed, high-accuracy control

MAZATROL PreviewG

Advanced hardware

State of the art CPU for unsurpassed operation speedHigh-response, high-speed machine motion

Optimum acceleration / deceleration for the reduction of cutting time

Tolerance control ensures high-speed corner cuttingImproved laser operation responsiveness

Laser control is improved to generate optimum laser power in the minimum timeImproved performance for fly cutting and sharp edge cutting

Large 19” LCD display with touch screen operation

Operates similar to your smart phone / tablet for increased ease of operationSwitches

Large switches and high-visibility LED lights prevents operation errors.If a function button cannot be used during a particular operation,

it is clearly indicated by the button illumination.

Buttons and switches are grouped according to function for ease of operation.

5 process home screens

CNC for laser prcessing machines

MAZATROL PREVIEW 3

Unsurpassed speed of operation

15" touch screen

Organized screen layout for convenient operation. Fast access to frequently used displays, such as command screen, position screen and programming screen.