FJW-100/160

Process integration by 5 face machining / Large workpiece capacity/ High-power machining

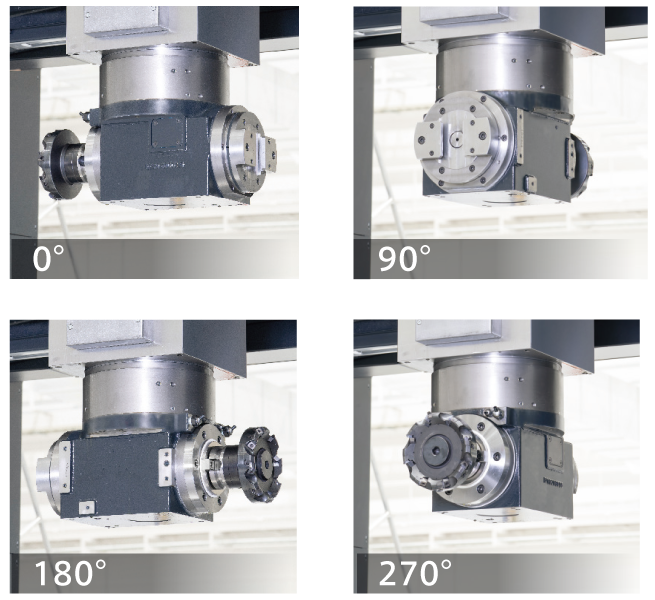

- 90°angle attachment tool for four face machining - standard equipment (5°indexing machining performed by EIA / ISO program)

- 6000 rpm spindle, 26 kW and 828 N・m (611ft・lbs) for high-power machining

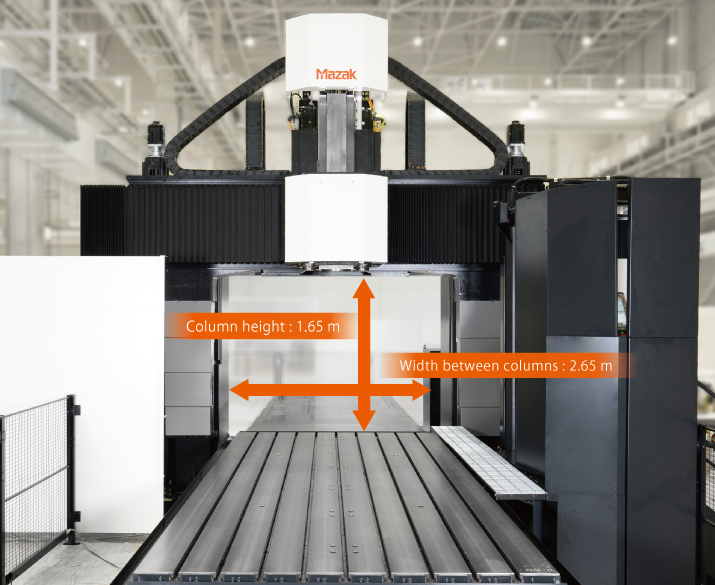

- Column height 1650mm (64.96") by utilizing cross rail with W-axis control

Angle head attachment

Automatic load / unload of angle head attachment, as well as automatic tool change (index 72 potions, every 5°) can be performed, allowing for automatic continuous machining as well as top face machining. (72 posion indexing per 5° performed by EIA / ISO program)

High torque 6000 min-1(rpm) spindle

Optional 6000 rpm high torque 828 N・m (611ft・lbs) (40% ED) spindle for heavy duty machining of steel or cast iron.

W-axis

Column height 1.65 m (64.96") by simultaneous operation of ram (Z-axis stroke of 0.8 m (31.5") and cross rail (W-axis) for tall workpiece machining

Machine Specifications

| Specification | Values | |

|---|---|---|

| Capacity | Table Right/Left | 4000 mm / 157.480 in |

| Table Longitudinal | 2000 mm / 78.740 in | |

| Spindle | Spindle Taper | BT50 |

| Maximum Speed | 6000 rpm | |

| Magazine | Number of Tools | 50 |

| Feed Axes | Travel (X Axis) | 4250 mm / 167.32 in |

| Travel (Y Axis) | 3200 mm / 125.98 in | |

| Travel (Z Axis) | 800 mm / 31.50 in | |