FF-n5000/40

Compact high speed horizontal machining center for mass production

FFn-5000/40

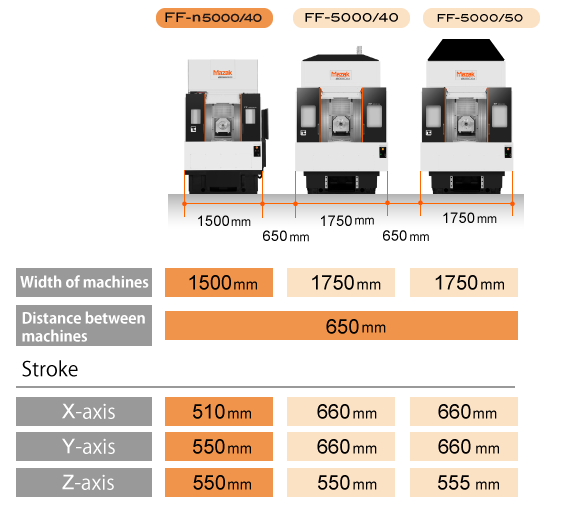

- Compact floor space

Suitable for mass production machining line of every size of parts from small size parts to large components such as cylinder blocks. - High productivity

Reduced non-cutting time thanks to high speed acceleration and rapid traverse rate. - High reliability

All machine linear motion is in the column to isolate the ball screws from machined chips.

Tools are directly changed to/from the spindle to the tool magazine to ensure high reliabiliy. - Automation

Fixed table construction provides convenient automatic fixture mounting for exceptional versatility.

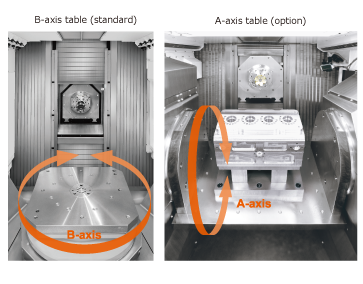

Machines with the standard B-axis machine and machines with the optional A-axis can be integrated in the same production line.

- MAZATROL SmoothC, the advanced CNC designed for ease of operation - standard equipment

- The MAZATROL SmoothC CNC is standard equipment and the Fanuc 32i is optionally available.

|

|

Note : Maximum workpiece width is 674mm because the width of front door is 674mm.(φ720 is maximum workpiece diameter including jig.)

Machine Specifications

| Specification | Values | |

|---|---|---|

| Capacity | Pallet Size | 500 mm |

| Maximum Workpiece Diameter | 720 mm | |

| Maximum Workpiece Height | 715 mm | |

| Spindle | Spindle Taper | BT40 |

| Maximum Speed | 12000 rpm | |

| Magazine | Number of Tools | 20 |

| Feed Axes | Travel (X Axis) | 510 mm |

| Travel (Y Axis) | 550 mm | |

| Travel (Z Axis) | 550 mm | |