Hybrid multi-tasking machines

- Produce gear without dedicated gear cutting machine

- Perform high accuracy gear cutting on the INTEGREX AG plus measurement and machining compensation

- Integrated processing ensures minimum production lead time for gear processing

Gear Cutting

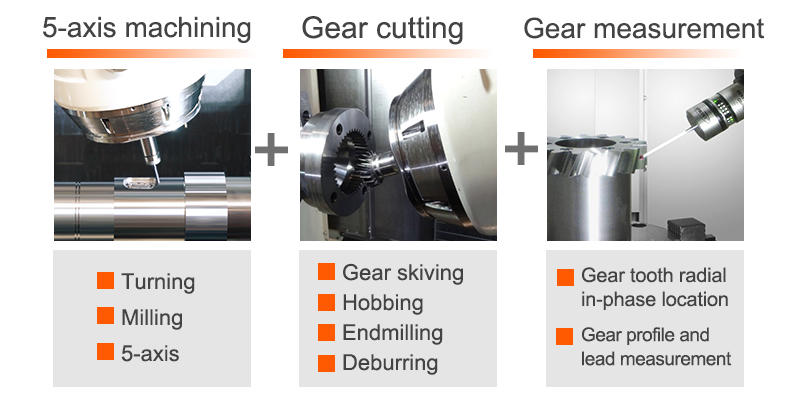

The integration of INTEGREX multi-tasking with gear cutting and measurement

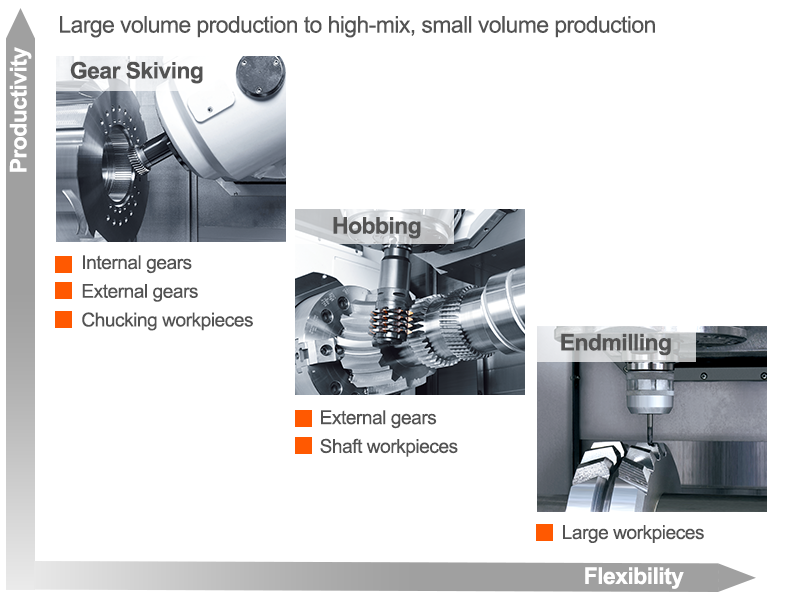

Perform a variety of High-accuracy gear machining

Smooth Gear Cutting

Conversational programming of high accuracy gear cutting and gear measurement

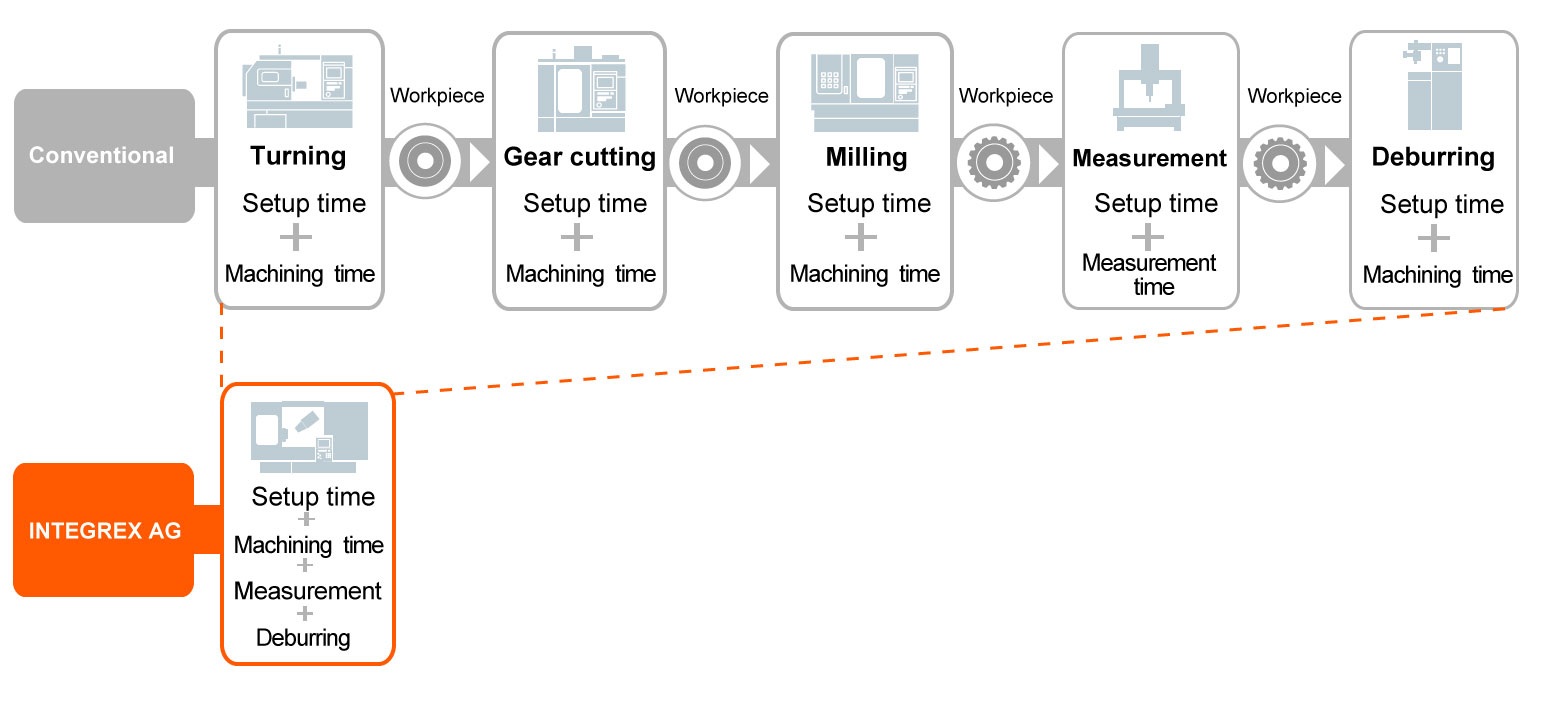

Operation flow

Programs are easily made in a short period of time by just inputting gear data

Protection of workpiece, tool and spindle

|

|

|

|

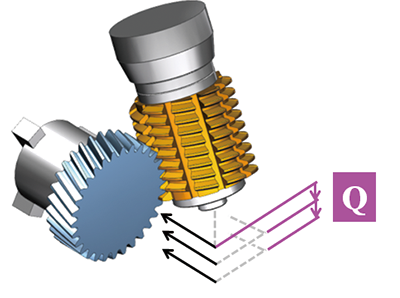

Gear Measurement

Gear teeth probing by touch sensor

When using a new cutter or regrind tool, a gear tooth can be probed by a touch sensor to determine the required amount of compensation. This same process can also be used to determine the in-phase positioning of other machined features, such as deburring using a ball endmill or locating a bore on a workpiece face.

Note : Compensation is manually entered for remachining

Gear profile and gear lead measurement (Option)

The gear profile and gear lead can be inspected on the machine by using an optional scanning probe. Measurement results are simply shown on the CNC display.

Benefits of gear machining by multi-tasking machine

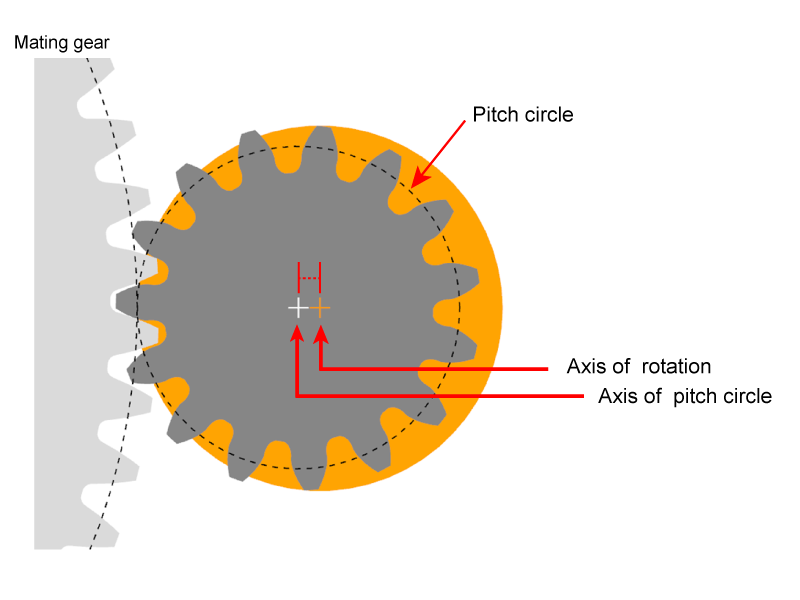

Higher accuracy

For maximum gear accuracy, center of workpiece rotation and center of pitch circle must be same. If gear blank is turned on lathe and then moved to gear hobbing machine, there will be some displacement between the centers. By INTEGREX DONE IN ONE® processing, the centers of the workpiece rotation and the pitch circle center are the same, providing the maximum gear accuracy.

Process integration

Gear processing that used to be performed by multiple machines is now completed by just one machine.

This revolutionary process integration reduces production lead time.