About 80% of CO₂ in the product life cycle is emitted at the time when a machine is in use at customer's factory.

We will contribute to reducing the environmental impact at our customers' factories by developing new models

and new functions with the consideration of saving energy.

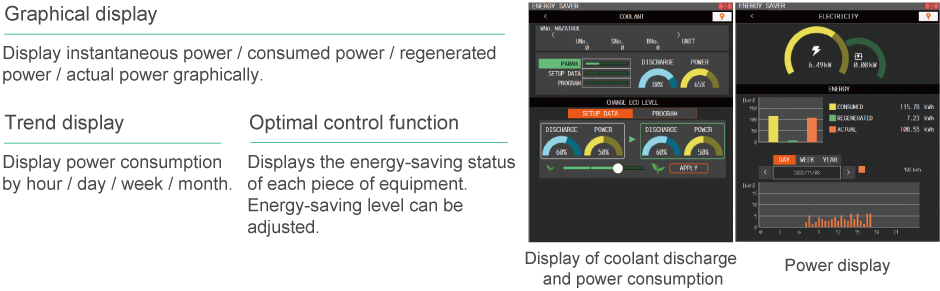

Visualization of machine power consumption with MAZATROL (Energy Saver)

Energy consumption and the regenerative power produced through the energy-saving equipment can be viewed visually on the MAZATROL CNC system - control / management of coolant and other equipment.

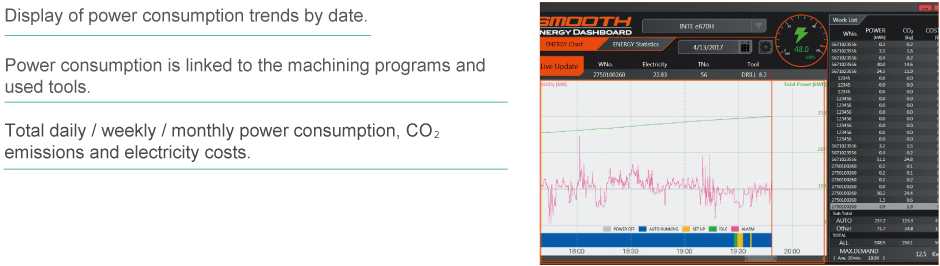

Energy Dashboard Plus contributes to energy saving of the entire factory

Multiple machines in a factory can be monitored by utilizing Energy Dashboard Plus of Smooth Monitor AX, our monitoring software. Using a sensor box, the operation of other manufacturer's equipment can also be monitored to save energy of the entire factory.

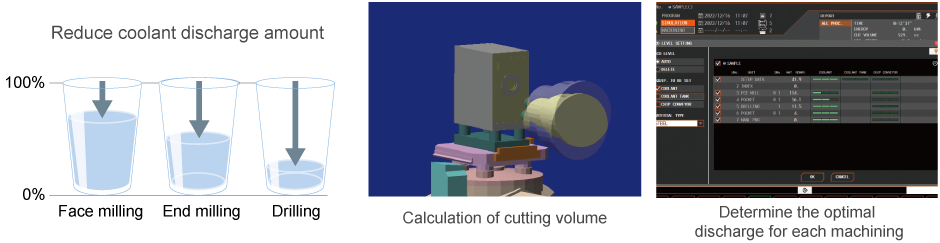

Optimal control of coolant and standby power with MAZATROL (Energy Saver)

Optimal control of coolant discharge amount

Energy saver automatically determines the optimal coolant discharge for energy-saving machining.

◎The cutting volume is calculated by simulation → The optimal discharge amount is automatically determined

Auto power off for lower energy consumption

The machine worklight, CNC screen, chip conveyor, cover coolant and other equipment can be set to energy-saving mode with Energy Saver. The off time after standby can be set for each equipment, reducing power consumption.

High energy-saving chiller unit

Improved refrigerant inverter optimizes cooling capacity according to the spindle load during machining, achieving a higher energy saving rate.

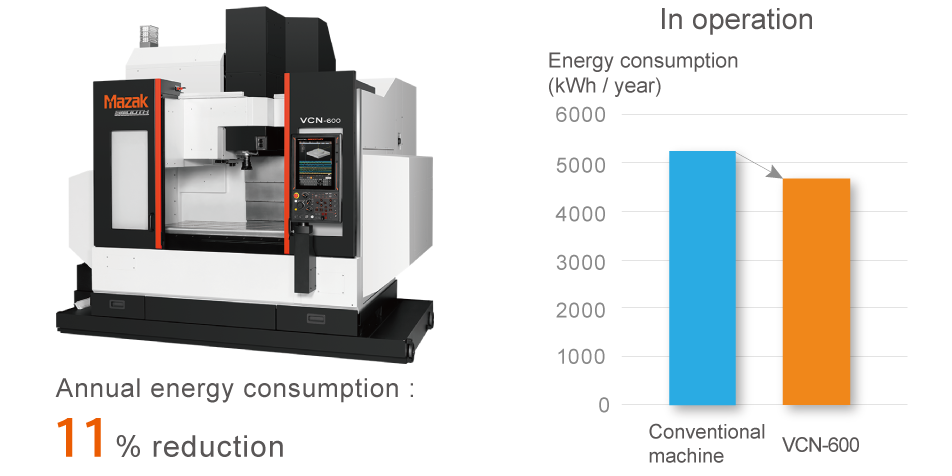

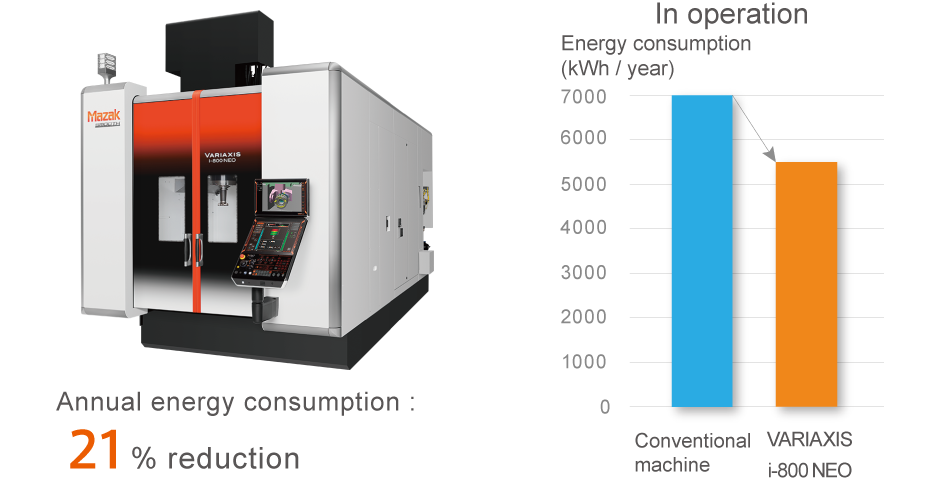

Significantly reduced CO₂ emissions during machining

Hydraulic unit utilizing accumulator as well as an inverter type chiller unit resulting in considerable reduction of energy consumption in operation.

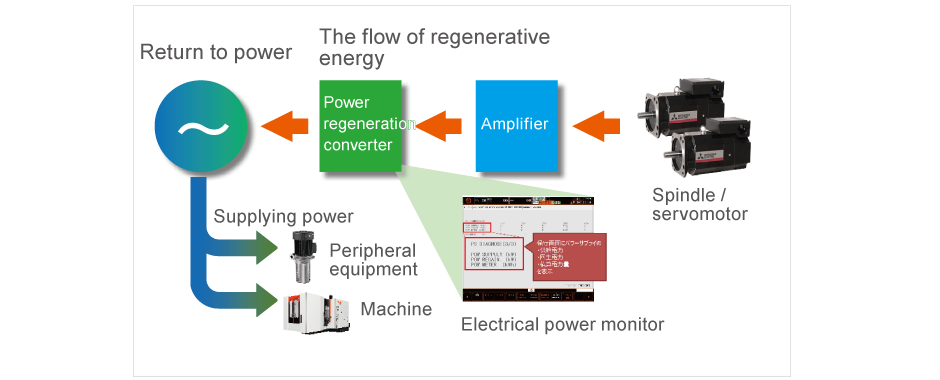

Regenerative electric power system

The power regeneration converter recovers the energy generated by acceleration/deceleration of the spindle motor and servomotor. Recovered energy is supplied to other equipment for effective energy saving. Regenerative electric power system is available for all Mazak models to reduce CO₂ emissions.