SMART Manufacturing Thanks to Smooth Technology

Today manufacturers everywhere face many challenges - constantly striving to reduce production costs, increasing the use of automation, a growing shortage of skilled employees among many others. "The Mazak iSMART FactoryTM" technology can be used to meet manufacturers' demands to establish production plants using the IoT. By utilizing advanced Mazak machine tools together with software, we can effectively support your goal of realizing data-driven manufacturing for higher productivity.

|

Mazak iSMART FactoryTMBy incorporating IoT and automation technologies, the Oguchi Plant began operation as a Mazak iSMART FactoryTM utilizing networking, monitoring and production big data analysis in order to realize higher productivity and efficiency. VIDEO |

|

Mazak Oguchi Sheet Metal FactoryAdvanced production system for sheet metal components with unsurpassed productivity and efficiencyVIDEO |

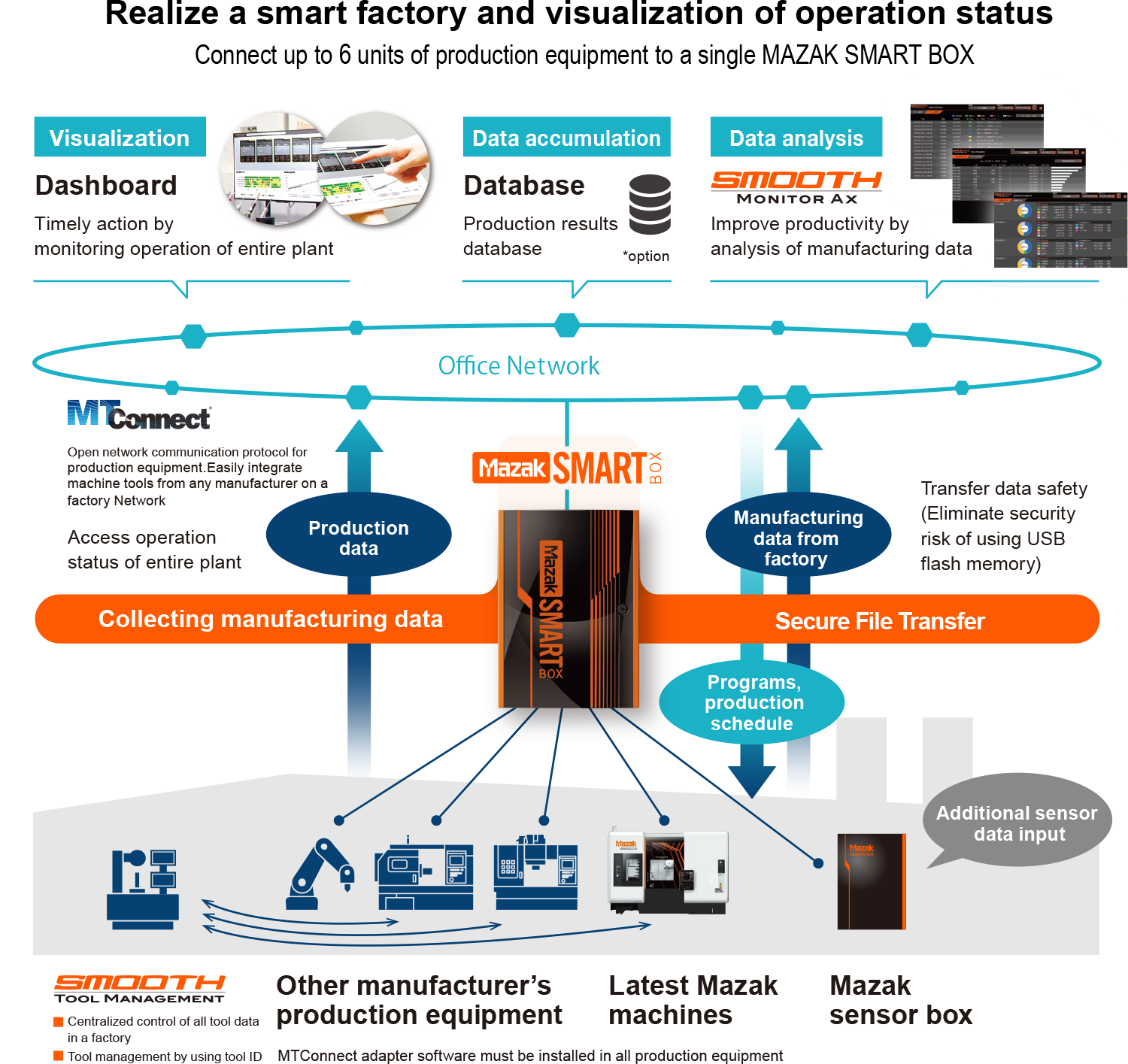

MAZAK SMARTBOX TM

Software and hardware to realize a smart factory

Using MTConnect as the foundation, the MAZAK SMARTBOXTM connectivity of machines and other production equipment provides enhanced monitoring and analytical capabilities including advanced cyber security protection.

Data gathering and analysis resulting in improved productivity and efficient factory management.

Mazak smart box is specially designed for IoT by preventing unauthorized access.

- Working with any machine regardless of manufacturer, model and age

- Secure and safe network connection

The MAZAK SMARTBOXTM enhances factory management for higher productivity.

MAZAK SENSOR BOX

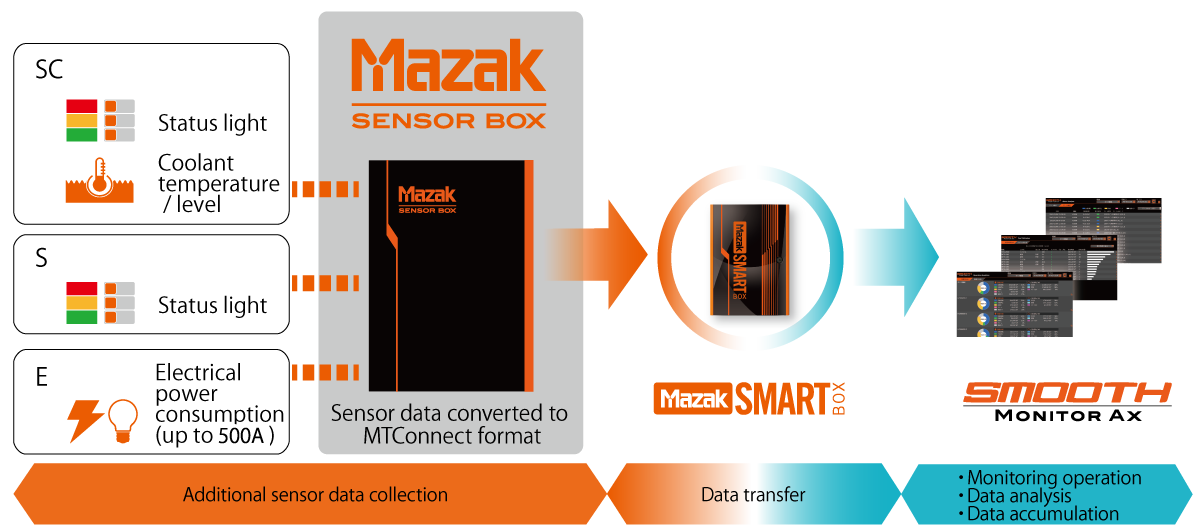

Sensor data converted to MTConnect format

The data collected by the Mazak SENSOR BOX is converted to the MTConnect format.

Three types of Sensor box:

- SC is used to obtain data from a machine status light and coolant temperature, level

- S is used to obtain data from a machine status light

- E is used for electrical power consumption data