↑ Please click to watch FMS video and simulation.

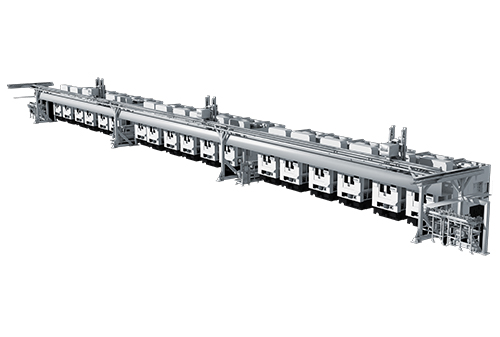

PALLETECH

High productivity automation system

Automation system with pallet transfer for higher productivity

- Automatic pallet transfer with fixtures and workpieces for multi-product machining

- Optimizing the machining schedule - shorten the idle time of machines and fixtures by simulation function

- Highly reliable machines and systems, which enable improvement of the system operation rate

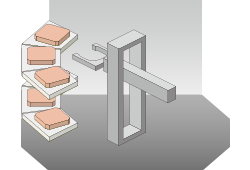

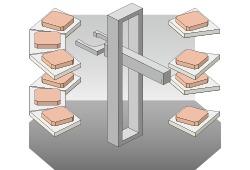

FLEXIBLE PALLETECH EXPANDABILITY

Flexible system expansion is available in response to changing production volume. Pallet stocker(s), loading station(s) and machines can be added in response to increased production requirements after the initial system installation.

Different model can be combined

Horizontal machining center, Simultaneous 5-axis machining center and multi tasking machine can be combined in one PELLETECH system.

MODULAR DESIGN

Pallet stocker

|

The rail for the loader and the chip pan are integrated with the pallet stocker in order to provide convenient system expansion.

The PALLETECH HIGH RISE SYSTEM features a 2-level pallet stocker with a minimum floor space requirement. |

|---|

Pallet loader

|

Pallets are transferred from the pallet stocker to the loading station and then to a machining center by the pallet loader.

The pallet loader features high speed acceleration and positioning to eliminate non-productive pallet waiting time. |

|---|

Loading station

|

The loading station is equipped with a safety door as standard equipment to maintain a safe working environment for the operator.

The PALLETECH system can be equipped with up to maximum of 8 loading stations. |

|---|

FMS control/ management software - unsurpassed ease of system operation to meet sudden changes in schedule.

MORE

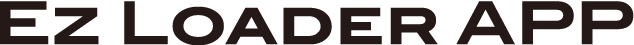

MAZATEC SMS

Mazak SMS with large capacity pallet stocker

- Maximum 16 machines, 8 setup stations, 240 pallets

- Flexible system length and height layout

- Maximum 6 types of stocker sizes available to meet your production requirements

- Stocker crane for high speed loading / unloading

- Loading/ unloading station for material pallets also available.

- Loading station allows access from two directions and area sensor for safety

- Smooth PMC controller for convenient machining management

- System integration with ERP available Software for integration with other computer network available upon request.

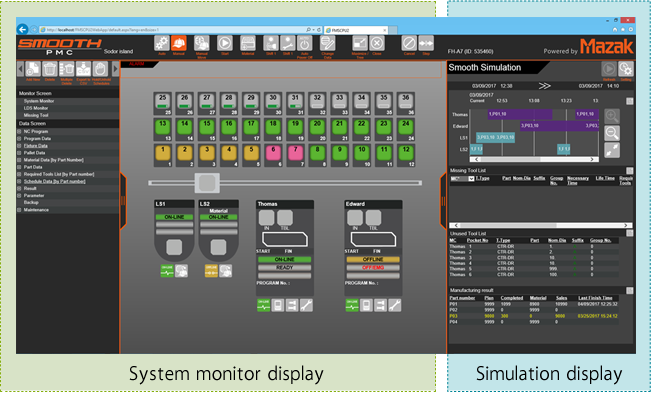

SMOOTH PMC controller machining management system

Production data and status can be monitored using the SMOOTH PMC controller management system. Fixture pallet synchronized with material pallet at loading station also available.

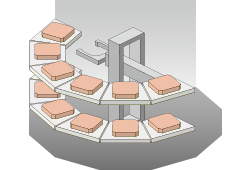

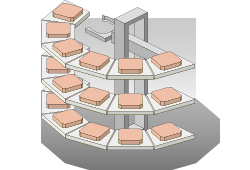

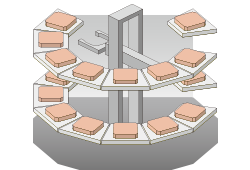

MPP(MULTI PALLET POOL)

Compact multiple pallet stocker system

The MPP (MULTI PALLET POOL ) is a system to meet the increasing worldwide demand for automation. It is designed to provide high productivity for multiple variety, small lot production. MOVIE

The operation and management of the MPP is performed by the same software used by the Mazak's FMS system, which is highly regarded worldwide for its ease of operation and high productivity MORE

- When compared to the PALLETECH system, the same amount of pallets can be stored in a smaller floor space.

- 6, 12 and 18 pallet storage capacities are available.

| 6PC |

|---|

|

|

|

| 3 pallets ×2 levels |

| (6 pallets + 1 loading station) |

| 12PC |

|---|

|

|

|

| 6 pallets ×2 levels |

| (12 pallets + 1 loading station) |

| 18PC |

|---|

|

|

|

| 6 pallets ×3 levels |

| (18 pallets + 1 loading station) |

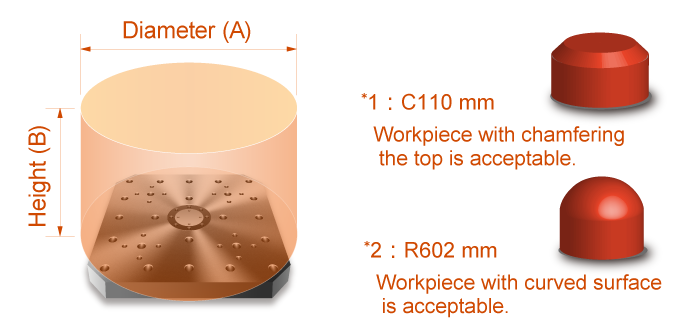

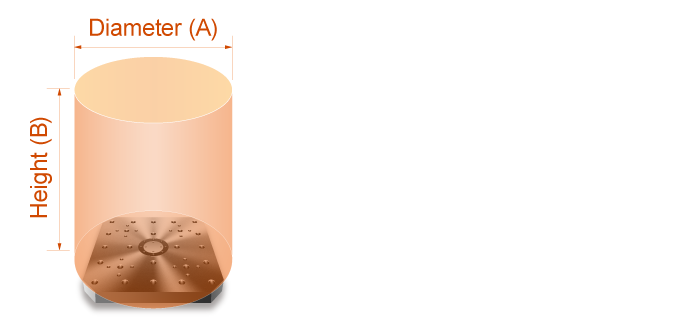

| Workpiece specifications | Pallet size | Max. load* | Max. workpiece size* Diameter (A) × Height (B) |

|---|---|---|---|

| VARIAXIS i-600 | □400 mm | 300 kg | Φ600 × 425 mm |

| VARIAXIS i-700 NEO | □500 mm | 600 kg | Φ730 × 500 mm |

| VARIAXIS i-700T | Φ610 mm | 600 kg | Φ730 × 500 mm |

| VARIAXIS i-800 NEO | □500 mm | 700 kg | Φ730 × 500 mm |

| VARIAXIS C-600 | □500 mm | 500 kg | Φ730 × 450 mm (C110)*1 |

| HCR-5000S | □500 mm | 500 kg | Φ700 × 643.6 mm (R602)*2 |

- When compared to the PALLETECH system, the same amount of pallets can be stored in a smaller floor space.

- 10 and 16 pallet storage capacities are available.

| 10PC |

|---|

|

| 5 pallets ×2 levels |

| (10 pallets + 1 loading station) |

| 16PC |

|---|

|

| 8 pallets ×2 levels |

| (16 pallets + 1 loading station) |

| Workpiece specifications | Pallet size | Max. load* | Max. workpiece size* Diameter (A) × Height (B) |

|---|---|---|---|

| HCN-4000 NEO | □400 mm | 400 kg | Φ630 × 900 mm |

| HCN-5000 NEO | □500 mm | 700 kg | Φ800 × 1000 mm |

| HCN-5000/50 | □500 mm | 700 kg | Φ800 × 1000 mm |

RCC

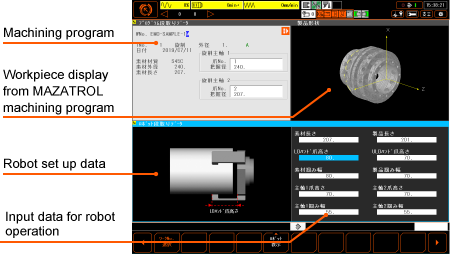

Management software for the robot cell

Dedicated management software for high-mix, low-volume production utilizing a robot ― operator can easily make the production schedule for extended periods of operation and check resources on the dedicated screen. [OPTION]

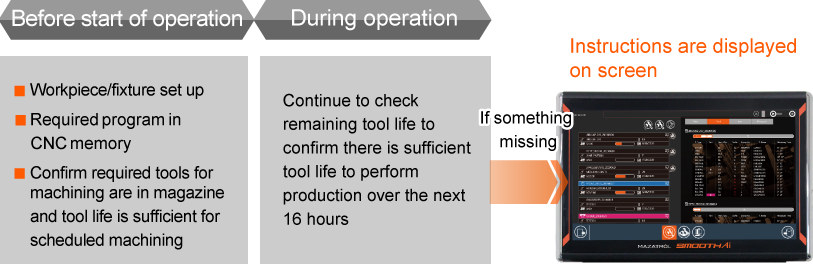

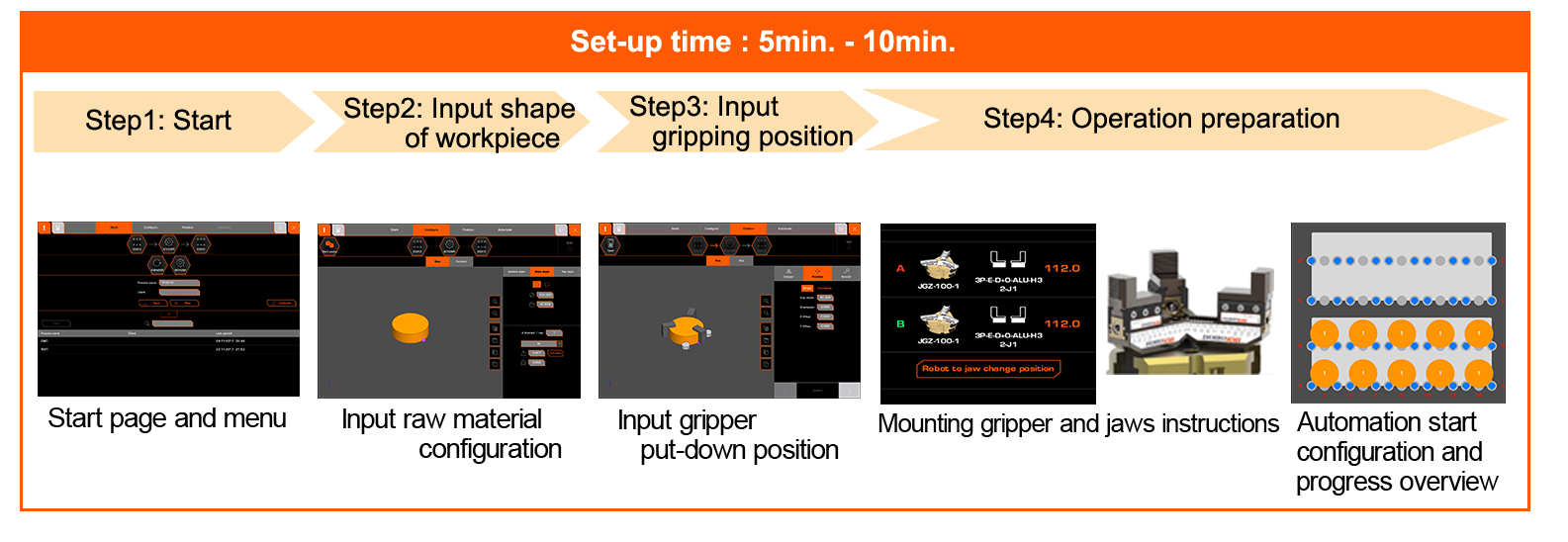

Functions to reduce automatic operation setup time

Resource check

- Prevent missing items which will stop automatic operation

Smooth RCC displays missing programs and tools thanks to resource check. During automatic operation, real-time tool simulation displays tools which have short remaining tool life to indicate which tools must be setup.

Robot setup assist

- Fast and easy robot setup

Automatically makes robot programs by inputting length of material, diameter and robot hand specification into the MAZATROL SmoothAi. For exceptional ease of operation, this conversational programming eliminates robot teaching.

|

|

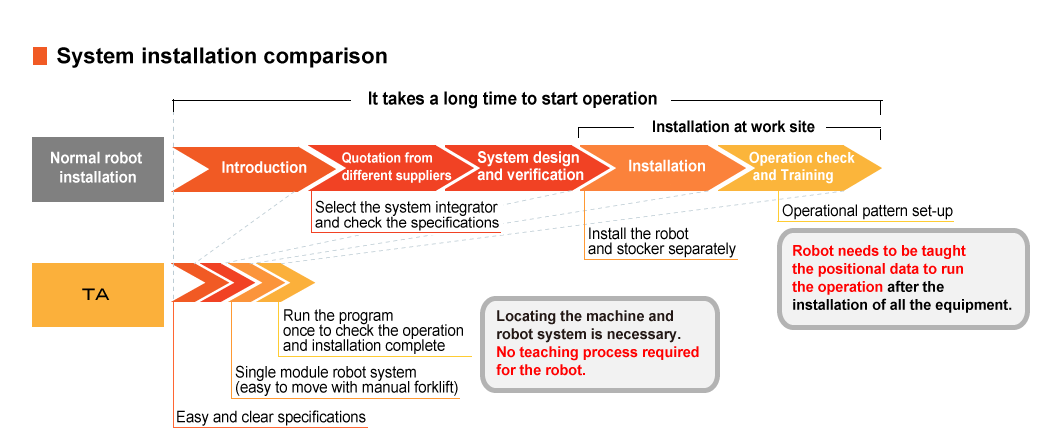

TA (Turn Assist)

Automation system for turning centers without complicated robot teaching

Integrated system - hardware and software

Designed for safety and ease of operation

If entry of a person into the system area is detected while the robot is operating,

its motion will decelerate and stop.

Safety fence not required on system front and right side.

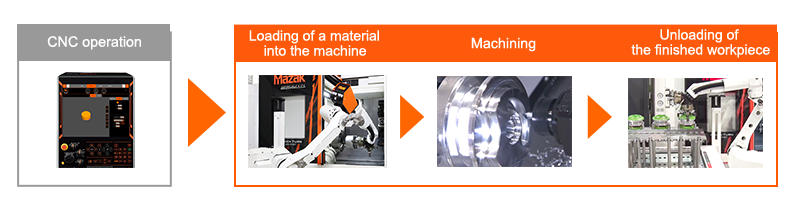

Automatic system operation

- Automation from loading raw material to unloading finished workpieces Turn Assist consists of a robot, Parts stocker and Smooth TURN ASSIST (system software).

- Stocker

|

|

Wide range of specifications to meet your requirements

| Specifications | TA-12/200 | TA-20/270 | TA-35/270 | |

|---|---|---|---|---|

| Material | Max. material diameter |

Φ200 mm | Φ270 mm | Φ270 mm |

| Max. material weight |

7.0 kg (3.5 kg X 2) | 14.0 kg (7.0 kg X 2) | 26.0 kg (13.0 kg X 2) | |

| Dimensions | Width × Depth × Height |

1489 × 1460 × 2456mm | 1920 × 1460 × 2456mm | 1920 × 1460 × 2456mm |

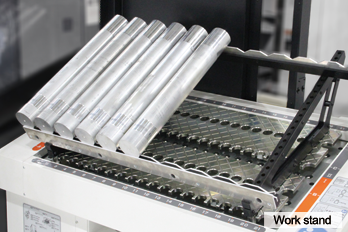

Shaft workpiece TA-20/270, TA-35/270

-

Can load the shaft workpiece and unload the finished workpiece

Comprised of a 4-jaw gripper for shaft workpiece, work stand for stocker and Smooth TURN ASSIST(system software)

-

Complete a workpiece setup in just 10 minutes

The built-in CNC system software (Smooth TURN ASSIST) provides easy system setup without requiring an operator familiar with robots. Using the preset outer diameter, length, and machining quantity of the material and finished part instructions are displayed for 1) loading the stocker with material, 2) mounting the finished workpiece positioning support rod, and 3) mounting the robot hand chuck jaw. Setting the material height position is automatic.

| Specification for shaft workpiece | TA-20/270 | TA-35/270 | |

|---|---|---|---|

| Diameter | Φ10 ∼ Φ80 mm | ||

| Length | 200 ∼ 800 mm | ||

| Max. Weight | 14 kg(Should not be unbalanced) | 25 kg(Should not be unbalanced ) | |

Smooth TURN ASSIST (system software)

By inputting raw material and finished workpiece data, Smooth TURN ASSIST prepares the robot for operation

System introduction

TA can be installed in front of the machine and start operation immediately after being installed.

Note : This system is compatible with machines equipped with MAZATROL SmoothG.

(QUCIK TURN with SmoothC can be field-installed.)

The following TA compatible optional equipment is required on the machine side.

・Spindle orientation

・Automatic door

・TA cable connection port

・Advanced robot interface(EtherNet/IP)

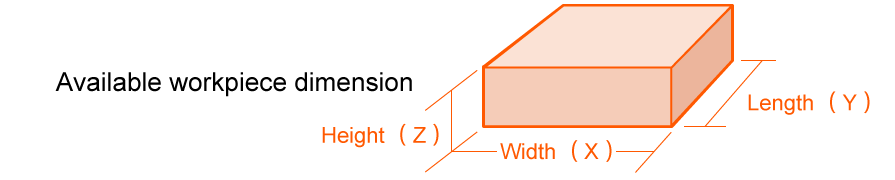

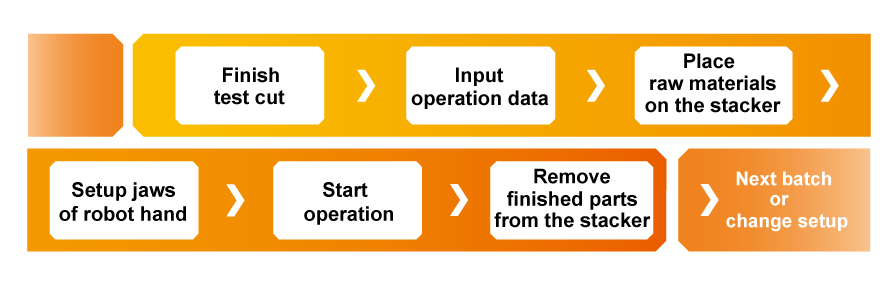

MA (MILL ASSIST)

Automation system for machining centers without complicated robot teaching

Higher productivity with easy operation

- Multiple machines can be operated by one operator

- Waiting time of an operator can be reduced by automatic operation

- Automatic workpiece loading by a robot stables the quality of the finished parts

- Easy and smooth setup by automatic operation software

| Available workpiece dimension | MA-20/400 | MA-35/400 | |

|---|---|---|---|

| Width (X) | 30 mm ~ 400 mm | ||

| Length (Y) | 32 mm ~ 150 mm | ||

| Height (Z) | 30 mm ~ 200 mm | ||

| Max. weight | 14 kg (7.0kg × 2) | 28 kg (14.0kg × 2) | |

Example

Continuous automatic operation

Smooth MILL ASSIST (Automatic operation software of the robot system)

Software for conversational operation

|

|

Note:This system is applicable for MAZATROL SmoothG.

The following optional equipment are required on a machine.

*1 : Not all the machine has safety cover.

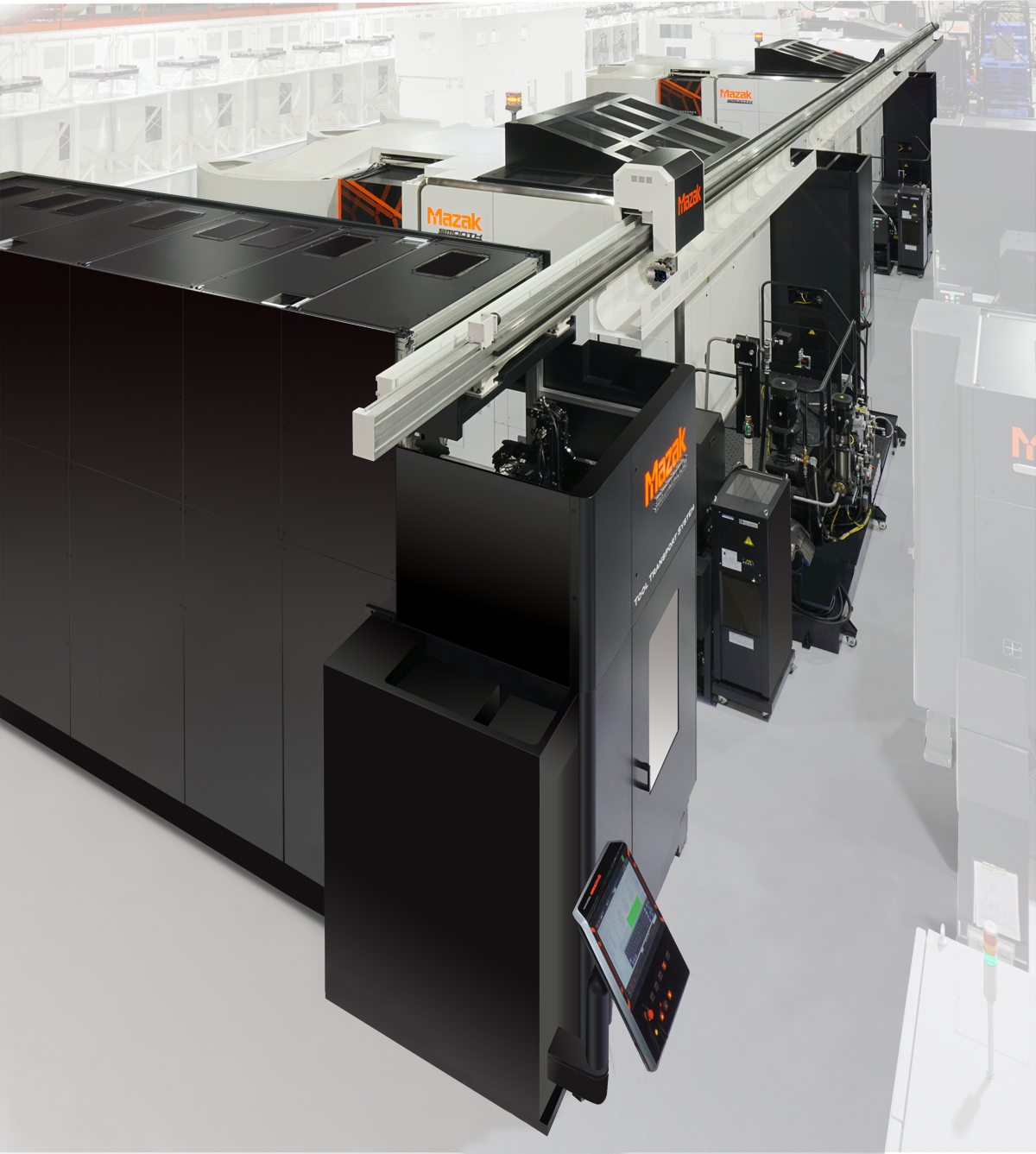

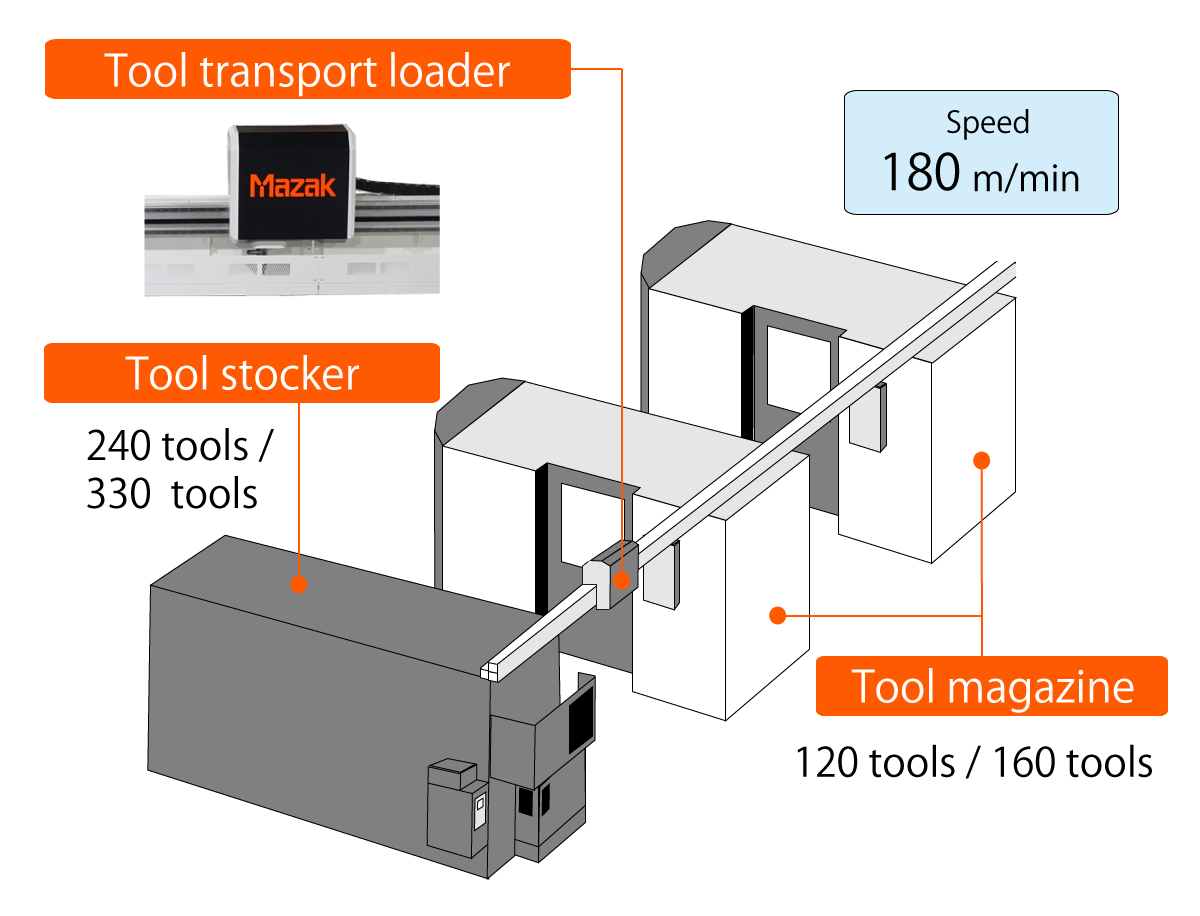

Tool transport system

The tool transport system automatically transfers tools

from a central tool stocker directly to the tool magazines of machines in a system.

Tools are automatically delivered to machines based on the machining schedule in order that operation will not be stopped due to missing tools. The operator can load setup tools into the single central tool stocker which supplies tools to multiple machines in a system.

For convenient tool management, the Smooth PMC controller performs production simulation based on the current system load and machine status to forecast required tools and expired tools to be removed.

Example system

A unique tool can be automatically shared between multiple machines resulting in lower tooling expense.

Gantry Loader

Ease of workpiece transfer and loading/unloading

High speed, high accuracy workpiece transfer and loading / unloading for unmanned operation over extended periods of time. Different specification work loader hands and work conveyors are available for a wide range of Mazak machine tools.

CNC turning centers ・Multi-tasking machines

New Gantry Loader system with swing motion, lowering the machine height

- Gantry Loader features a compact design with a unique structure, lowering the machine height.

- Further reduces the work loading / unloading time.

- The part conveyor can be integrated with multiple machines.

- High speed gantry loader ensures higher productivity

- 2-pallet workpiece conveyor at front and rear allows setup of next job during machining of the current one

- Wide variety of gantry loaders to meet your production requirements

- Flexible installation - conveyor can be located on machine right or left side, measurement equipment can be added and can connect 2 machines

- By adding automatic door and robot I/F, gantry loader can be field installed on QUICK TURNs

- Different specification work loader hands and gantry loaders are available to meet a wide range of production requirements

- Designed for large volume production for automotive components -for the machining of components such as engine blocks and cylinder heads

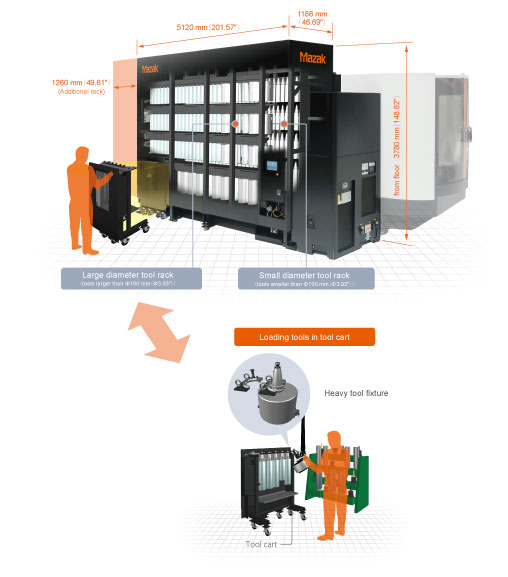

- Easy loading of tools into the tool cart that is directly inserted into the tool dock

- Loading/unloading tools outside the magazine ensures safe setup operation

- Convenient transportation by tool cart

- Large tools that normally require manual loading are handled by the automatic tool changer

- Max. tool diameter Φ360 mm (Φ14.17"), max. tool length 1000 mm (39.37"), max. tool weight 40 kg (88 lbs), max. tool moment 80 N・m (59 ft・lbs)

- 40 kg (88 lbs) tools can easily be loaded with the heavy tool fixture

- 70 tools can be added by the 1260 mm (49.61") extension at the rear of the magazine

- Designed for convenient system extension after the initial installation

- While normal flood coolant may fail to reach the cutting zone, SUPERFLOW ensures direct delivery to the cutting edge, reducing temperatures and improving tools’ cutting action

- SUPERFLOW helps to create small chips and efficiently evacuating them from the cut where chips are removed by the coolant resulting in extended tool life

- SUPERFLOW prevents coolant vaporization by heat and delivers coolant directly between the tool and workpiece, improving lubrication, tool life and surface finish

- Coolant pressure easily set by M-code (pressure range from 0 to 7.0 MPa)

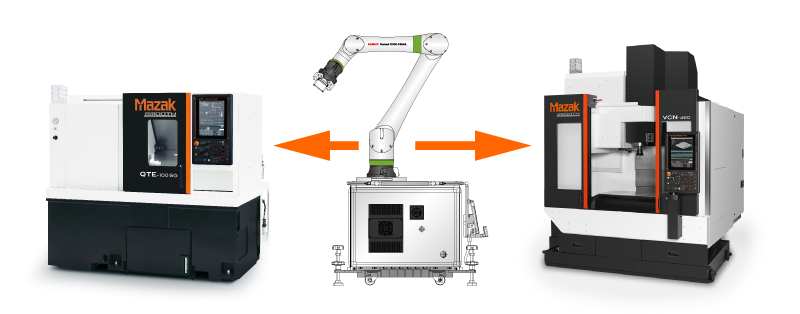

- Cobot (collaborative robot) × vision sensor × software for Mazak machines

- Applicable to Mazak small to middle size multi-tasking machines, CNC turning centers and vertical machining centers

| Applicable machines | Gantry loader |

|---|---|

| Multi-tasking machineINTEGREX i-H series | GL-100 / GL-150 / GL-200 / GL-300 / GL-400 / GL-500 |

GL series for extended periods of automatic operation

| Applicable machines | Gantry loader |

|---|---|

| CNC turning centerMULTIPLEX W series | GL-100 / GL-150 / GL-200 / GL-300 / GL-400 |

| Multi-tasking machine INTEGREX iseries | GL-50F / GL-75F / GL-100F / GL-150F / GL-200F /GL-300F / GL-400F / GL-500F |

New gantry loader meets a variety of automation requirements

| Applicable machine | Gantry loader |

|---|---|

| CNC turning centersQUICK TURN series* QT-COMPACT series | GL-30 / GL-50 / GL-100 / GL-150 / GL-200 / GL-300 |

*Not available for the QUICK TURN 400,450 series

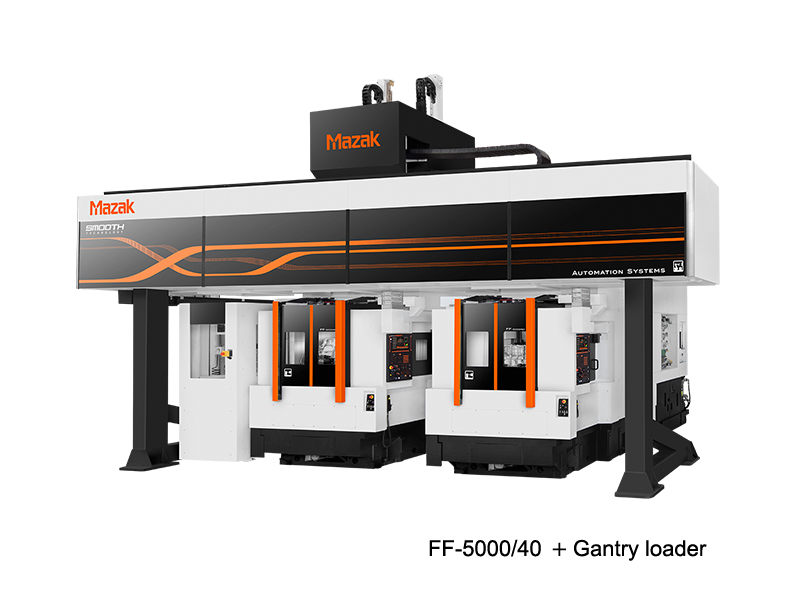

FF Horizontal machining center series

Compact production line with gantry loader

TOOLTECH

Compact rack-type magazine with large storage capacity

Tools are organized according to tool length and diameter for high space efficiency.

The high speed tool loader carries tools to the automatic tool changer.

206 tools can be stored in approximately the same floor space as a 120 tool chain magazine.

Tool cart

Large tools

Extensibility

SUPERFLOW coolant system

High-pressure coolant system for higher efficiency and productivity

|

|

|---|

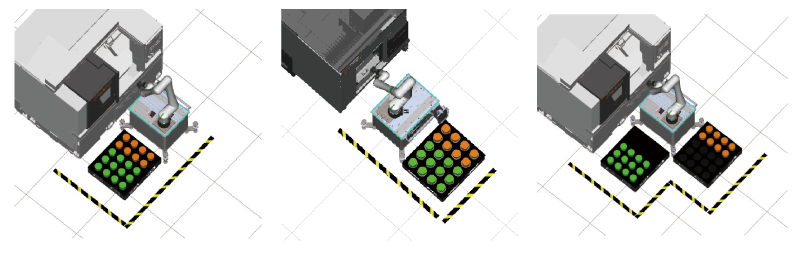

Ez LOADER

Automated system with Cobot

Ez LOADER 10, 20

Automated system with Cobot

Ez (Easy) operation, setup and custom

| Workpiece dimension - Round - |

Ez LOADER 10 | Ez LOADER 20 | ||||

|---|---|---|---|---|---|---|

| Diameter | Min. Φ50 mm - Max. Φ200 mm | Min. Φ50 mm - Max. Φ200 mm | ||||

| Length | Min. 25 mm - Max. 100 mm | Min. 25 mm - Max. 100 mm | ||||

| Max. weight | 5 kg | 10 kg | ||||

| Workpiece dimension - Square - |

Ez LOADER 10 | Ez LOADER 20 | ||||

|---|---|---|---|---|---|---|

| Length | Min. 20 mm - Max. 100 mm | Min. 20 mm - Max. 100 mm | ||||

| Width | Min. 30 mm - Max. 150 mm | Min. 30 mm - Max. 150 mm | ||||

| Height | Min. 15 mm - Max. 100 mm | Min. 15 mm - Max. 100 mm | ||||

| Max. weight | 5 kg | 10 kg | ||||

Ez Operation

Minimum number of steps required to get the system running.

Automatic operation is available by placing workpieces on the template and inputting numerical information for workpiece and table. Ez LOADER is flexibly adopted to customers' production requirements and floor layout.

Three template positions of workpiece placement

Ez Setup

Only 15 minutes required for system setup

Once the Ez LOADER is connected to a machine with a cable, it automatically recognizes the machine model. The robot position is automatically adjusted to the right position by reading three positioning markers*1 on a machine with its vision sensor.

*1:Positioning markers are put on the compatible machines of the Ez LOADER

The workpiece position is automatically adjusted by its vision sensor.

Image: Ez LOADER 30

Ez Custom

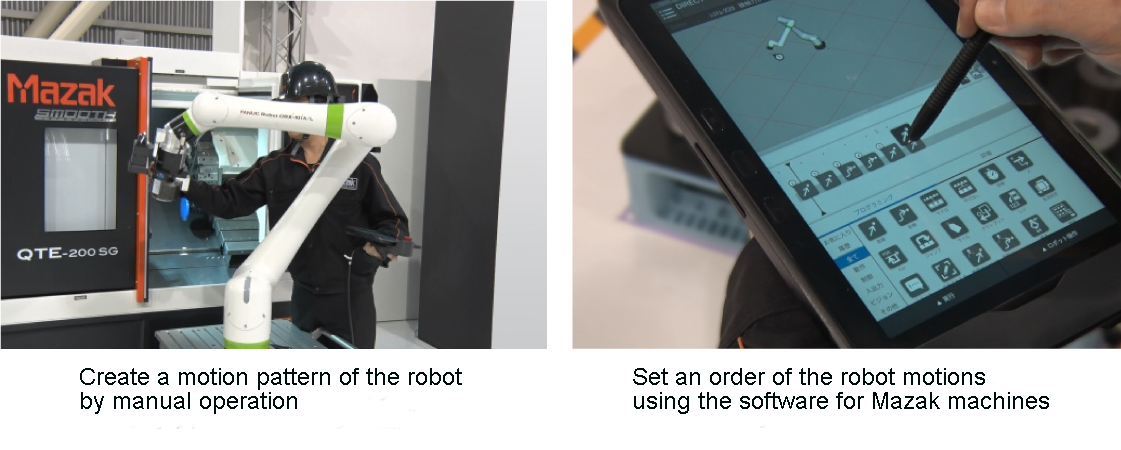

Easy to create an original motion / operation of the cobot

The original operation program is easily created by the direct teaching function of the robot and the Mazak machine operation command icons.

Ez LOADER 30

Collaborative robot operated by MAZATROL

| Workpiece dimension - Round - |

Single hand | Double hand (two-handed) | Double hand (one-handed) |

||||||

|---|---|---|---|---|---|---|---|---|---|

| Diameter | Min. Φ50 mm - Max. Φ200 mm |

Min. Φ50 mm - Max. Φ200 mm |

Min. Φ50 mm - Max. Φ200 mm |

||||||

| Length | Min. 25 mm - Max. 200 mm |

Min. 25 mm - Max. 200 mm |

Min. 25 mm - Max. 200 mm |

||||||

| Max. weight | 21 kg | 11 kg x 2 | 18 kg | ||||||

Flexible fence-less operation

Up to three pallets can be arranged for long hours of operation.

The fence-less design allows for flexible adaptation to the customer's production configuration and floor layout.