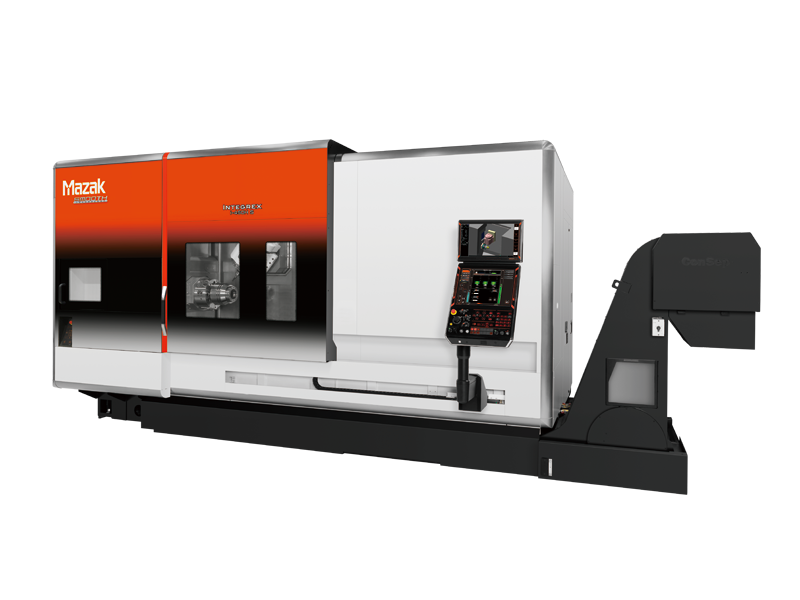

INTEGREX i-350H ST

Photo) INTEGREX i-450H S shown with optional equipment

Next generation multi-tasking machines

- Thanks to flat design of the front, the INTEGREX i-H series considerably improves peripheral equipment accessibility such as a robot and raw material stocker.

- Wide variety of turning and milling spindle specifications available

- New MAZATROL SmoothAi CNC system

Lower Turret

Thanks to balance cutting with the milling spindle and lower turret (simultaneous machining with two tools), productivity can be increased.

Lower turret standard specifications

12 position drum turret for expanded machining

|

Lower turret with rotary tools < option >

The lower turret is optionally available with rotary tools.

Milling can be performed simultaneously by the upper and lower turrets for improved productivity.

|

Automation

Bar feeder

Bar feeders can be used by the INTEGREX i-H series.

A bar feed interface is available for most of the widely used systems. Optional bar feeder scheduling for high-mix, small lot size production and set production is available.

INTEGREX i-450H ST shown

TA (TURN ASSIST)

The TURN ASSIST robot system does not require complicated robot teaching.

Thanks to the setup software, loading of workpieces on the stocker and robot movement are efficiently performed.

INTEGREX i-450H ST shown

Gantry Loader system

Gantry Loader(GL) features a compact design, lowering machine height. Its unique design also reduces loading / unloading time. The part conveyor can be installed on either left or right sides of the machine and can be integrated with multiple machines.

INTEGREX i-200H ST shown

Mazak AUTO FLEX CELL

The robot system can perform high-mix, low-volume production by a floor mounted robot.

INTEGREX i-450H ST shown

Auto jaw changer

Automatically change jaws which are stored in stocker by program command.

Next generation MAZATROL Smooth CNC system

Machine Specifications

| Specification | Bed Length - 1500U mm | |

|---|---|---|

| Capacity | Maximum Swing | 670 mm / 26.38 in |

| Maximum Machining Diameter | 670 mm / 26.380 in | |

| Maximum Bar Work Capacity | 80 mm / 3.2 in | |

| Maximum Machining Length | 1519 mm / 59.800 in | |

| Main Spindle | Chuck Size | 10 in |

| Maximum Speed | 4000 rpm | |

| Second Spindle | Chuck Size | 10 in |

| Maximum Speed | 4000 rpm | |

| Milling Spindle | B-Axis Travel | 240° |

| Magazine Capacity | 38 | |

| Maximum Speed | 12000 rpm | |

| Turret (Lower) | Number of Tools | 12 |

| Feed Axes | Travel (X Axis) | 695 mm / 27.36 in |

| Travel (X2 Axis) | 220 mm / 8.66 in | |

| Travel (Y Axis) | 300 mm / 11.81 in | |

| Travel (Z Axis) | 1585 mm / 62.40 in | |

| Travel (Z2 Axis) | 1539 mm / 60.59 in | |